Pallet Dispenser Essentials

Rob Stepanek | 24 August 2016

One of the most vital parts of any palletizing system is a pallet dispenser. Pallet dispensers automate the infeed of an empty pallet at regular intervals into the system. This automatic infeed increases the overall efficiency of the system by leaving operators available to tend to different parts of the same line, or even a different line altogether. There are a variety of mechanisms that can be employed to deliver pallets. At Bastian Solutions, we utilize two designs – fork-style and lift-style.

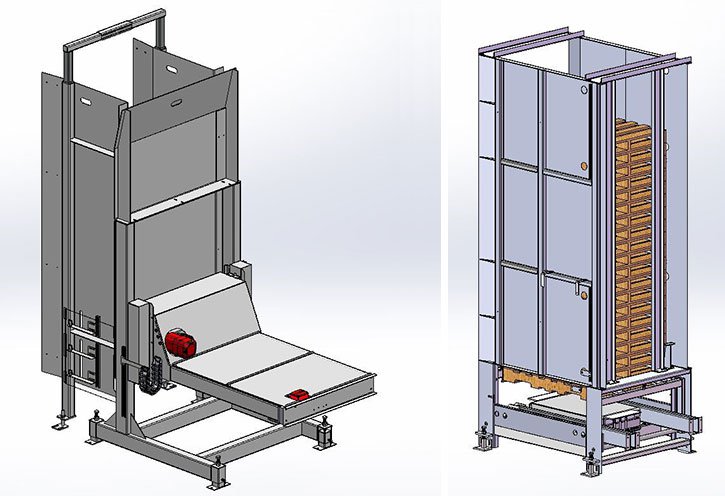

Fork-Style Pallet Dispenser

Our fork-style pallet dispenser uses specially designed fork lift tines to lift the stack of pallets off the conveyor. This allows the bottom-most pallet to convey out of the dispenser. The tines then lower the stack back onto the conveyor, retract, rise up, and extend into the second pallet from the bottom. Once the tines have been extended into the pallet, they lift slightly, allowing the lower pallet to be conveyed to the load building position. Once that pallet has cleared, the process is repeated.

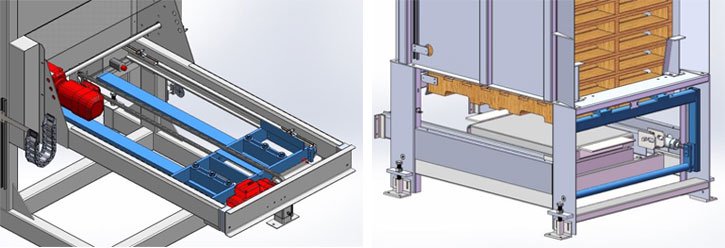

Lift-Style Pallet Dispenser

The lift-style (illustrated by the views below) utilizes a hydraulic lift situated between 2 strands of a chain conveyor. The lift will position the stack at a programmed height, then short arms will extend to catch the second-from-the-bottom pallet. The bottom pallet is then lowered onto the chain conveyor. Once this pallet has conveyed out of the dispenser and onto the next conveyor, the lift will raise up to support the stack, the short arms are retracted, and the process repeats.

Benefits and Applications

Both of these designs have different attributes that make them appealing for varying types of applications. Points to consider when selecting a suitable pallet dispenser include:

- Number of pallets you need to store

- Desired orientation when loading full stacks of pallets

- Degree of flexibility for changing the pallet size

- Condition of the pallets you are using

Ceiling clearance and pallet weight both play an important role in determining how many pallets a dispenser can hold, but Bastian Solutions’ standard design allows for up to 20 pallets, and with modifications, more can be accommodated. Having more pallets in a stack increases the time between refilling the stacker, which allows the operator more time to perform other tasks. Both of our standard dispensers are oriented to load the pallet stack inline with the takeaway conveyor. However, modifications can be made to accommodate loading perpendicular to the conveyor if necessary. If the application requires the dispenser to be flexible across multiple pallet sizes, our standard fork-style design is flexible to accommodate a wide range of pallet widths. This is important for customers wishing to palletize a variety of different SKUs. Pallet widths should always be specified at the beginning of a project as they can greatly affect the design. Lift-style pallet dispensers can accommodate some variation in pallet sizes as well.

Pallet Condition

Another important factor to providing a reliable, automated infeed of pallets is consistent pallet condition. Broken boards, exposed nails, and screws can all get jammed in the equipment and necessitate manual intervention in order to correct it. This is one area where the fork-style dispensers have an edge over the lift-style. The forks support many boards whereas the lift style catches just the outside edges – the most likely area for pallet damage to occur. One additional way to help prevent problems caused by poor pallet quality is through the installation of pallet dispenser containment doors. If boards in a pallet are missing, it could lead to an unstable stack of pallets. Containment doors are integral in preventing a stack from falling or tipping due to compromised pallet quality. Overall, the addition of containment doors to a new or existing pallet dispenser is a great way to improve personnel and equipment safety in your facility. These heavy-duty doors are very low maintenance and extremely easy to operate. Both manual and pneumatic options are available depending on the application and customer requirements. Typically, manual doors are recommended for lower rates, and pneumatic doors are used when a higher rate is necessary.  Have questions? Contact our team, and talk to an applications engineer at Bastian Solutions to discuss your automated pallet dispensing needs. We will work on a solution to get the right system for you.

Have questions? Contact our team, and talk to an applications engineer at Bastian Solutions to discuss your automated pallet dispensing needs. We will work on a solution to get the right system for you.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.