What Does a Material Handling Systems Integrator Do and How Can It Benefit My Business?

Sky Hernandez | 10 August 2016

The right material handling systems integrator should be more than a distributor and more than an integrator. Here’s what to look for in your next systems integration partner.

So you may be wondering why you have been re-directed by an OEM (original equipment manufacturer) to Bastian Solutions as a distributor of the equipment. Or, perhaps you stumbled across the Bastian Solutions website and are wondering what a systems integrator does and how that can benefit your business. Well, if you have a material handling need, a systems integrator such as Bastian Solutions can help you, and here’s how.

A distributor is a company that has ties to the original equipment manufacturer and supplies their goods to other businesses and end customers. For example, Bastian Solutions, as a distributor of the goods, will also be the local support for customers on behalf of the OEM, including sales expertise, customer application review, and equipment troubleshooting.

An integrator or systems integrator is a company that provides and integrates equipment, typically while also designing the solution for the customer’s process, using any connections the integration company might have for engineering design, equipment, controls, software, installation services, project management, etc.

In order to better understand material handling systems integrators as a distributor, let’s look at a few examples and how that can benefit your business. Integrators typically offer a wide array of material handling equipment; some offer only their own brands of equipment, while others, including Bastian Solutions, offer an array of brands and products to fit your specific needs.

Along with equipment, systems integrators should add value of expertise, application review, and local support, going above and beyond what a manufacturer is be able to provide. And with vendor connections across many states and countries, they can provide a solution for virtually any material handling need.

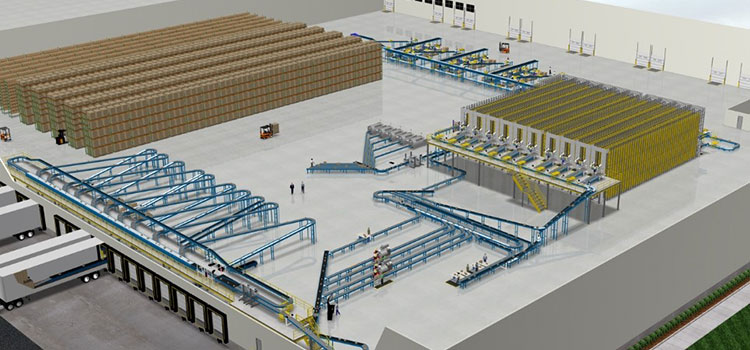

Bastian Solutions, as an integrator, can benefit your business by taking a complex material handling project and managing it all the way down to a turn-key system providing you a more efficient operation. For example, a customer may ask for a solution to get boxes from A to B while meeting desired rates, maintaining a certain floor plan, utilizing additional ancillary equipment, etc.

Bastian Solutions can design a system around those parameters, work with OEMs to provide the necessary equipment to do the job, line up installers to integrate the system into the customer facility, design and build the control panel, provide the software, and manage all aspects of the project through final acceptance. Then all that is left is to hand over the keys to the customer, along with some training, and allow them to take pride in their new system as it continues to help their operations flourish.

In a nutshell, material handling systems integrators are many things including a distributor, an integrator, an expert in the material handling industry, and much more. Whether you’ve found Bastian Solutions by accident when searching for conveyors, or you’ve only ever thought of us as a caster supplier, know that we’re here dedicated to helping you excel in your market and achieve your strategic business goals by providing the best material handling system solutions, innovative software, robotics, and automation equipment.

Sky is a Project Engineer with Bastian Solutions located in the Grand Rapids regional office and has over 4 year of material handling experience as well as 2 years of manufacturing experience. Sky attended the University of Toledo where he received a B.S. in Mechanical Engineering. As a Project Engineer, Sky has shown proven success in system design and project management for warehousing, distribution, and manufacturing operations. His expertise includes process optimization, CAD design, Six Sigma methodologies, and knowledge of a wide variety of material handling equipment.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.