What are Photo Eye Sensors, and How Do They Improve System Automation?

Blake Smith | 21 May 2019

For those unfamiliar, a photo eye (or photoelectric sensor, if we get technical) is a type of sensor commonly used in the material handling industry to sense the presence or absence of an object within the sensors range without physically touching the object. A photo eye primarily consists of an emitter - to emit light, and a receiver – to receive the emitted light. By monitoring the electrical output of the receiver, a control system can tell when there is an object in the path of the photo eye and even how far away the object is. These capabilities lend themselves well to a variety of controlled systems.

Types of Photo Eyes

There are three principal types of photo eyes used in the material handling industry (although this list is by no means exhaustive): through-beam, retro-reflective, and diffuse-reflective.

- A through-beam photo eye (shown below) has the emitter and the receiver in separate housings opposite each other– often on either side of a conveyor. This method is the most accurate and has the longest sensing range; however, it is also the most costly as it requires a separate emitter and receiver. Because through-beam photo eyes have the receiver on the opposite side, it does not face the same challenges regarding color, mirrored finishes, or short distances as the other methods– the tradeoff here is cost.

.png)

- A retro-reflective photo eye (shown below) has the emitter and receiver in the same housing with a reflector on the opposite side. This method is slightly less accurate than a through-beam sensor, and the sensing range is slightly shorter; however, it is also less costly than the through-beam method. Some challenges that retro-reflective photo eyes face include a dead zone at very close distances and sensing objects with mirrored finishes. A unique advantage is its ability to sense more transparent objects because the light passes the object location twice.

Note: this is the most commonly used method in the material handling industry.

.png)

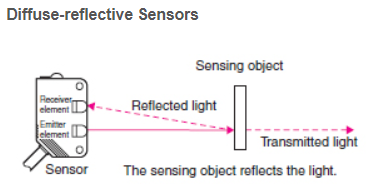

- A diffuse-reflective photo eye (shown below) has the emitter and receiver in the same housing with nothing opposite. This method is less accurate and has a shorter sensing range than the through-beam or retro-reflective sensors; however, it is also less costly than the other two methods. A challenge that diffuse-reflective photo eyes face is the light reflected off the object can vary with the characteristics of the object (such as smoothness, color, etc).

Photo Eye Applications

Photo eyes lend themselves well to use in control systems – especially conveyor system controls. The output from photo eyes are often used in conveyor controls to index a conveyor or trigger conveyor movement. In fact, complex conveyor systems with several transfers, merges, and accumulation lanes are often implemented using a series of photo eyes, as it allows the control system to know the location of the product being handled. In order to accomplish all this, photo eyes are often linked to PLCs, PC-based controls, and self-contained control systems (like Hytrol’s EZ-Logic System) that can output to an external control like a PLC.

Because photo eyes are very common in conveyor system controls, they are found in a wide variety of industries and in a wide variety of environments – from manufacturing to distribution. Whether they’re used to sense the presence of boxes (think Amazon) or to sense the presence of a part on a manufacturing line, photo eyes help keep lines running around the world.

We have extensive experience implementing control systems in all kinds of operations. For more information on how photo eyes can be implemented in your facility, please contact us. We can help you explore a range of options and figure out the best solution for your application.

References

Illustrations From: http://www.ia.omron.com/support/guide/43/introduction.html

Blake is a Bastian Solutions Project Engineer based in Novi, MI. He has a Bachelor of Science in Mechanical Engineering from Georgia Tech. As a Project Engineer, Blake works closely with the local Field Application Engineers to create proposals, design material handling systems, and manage projects.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.