Vectura ASRS Stacker Crane Offers System Flexibility

Johan Källvik | 04 January 2012

This post is written by Johan Källvik, Business Development Manager, at the Swisslog-Accalon Technology Center in Boxholm, Sweden.

Imagine a warehouse in which rows of full pallets could be stacked up to 165 feet in the air, one on top of another, on top of another. Then, with the ease and grace of a high quality machine, one of those pallets--weighing as much as 6,600 lbs--is gently lifted from its storage space and quickly brought to a worker at ground level. This is the amazing world of automated storage and retrieval systems (ASRS).

These automated systems have been perfected through the use of our stacker cranes. These cranes are the central component inside today's storage retrieval systems. They swiftly transfer pallets, containers, and even cars from storage slots within the ASRS to a pickup station outside the system.

Swisslog Stacker Cranes

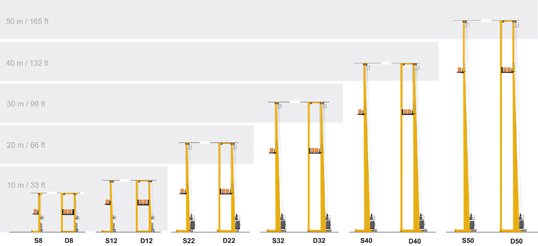

Swisslog has decades of experience in designing stacker cranes. In 1969, we produced our first one, and now we have delivered nearly 2,800 of them across the globe. Our latest development, the Vectura crane is built on our years of experience and with the latest technologies available, resulting in a reliable and price competitive crane built to last. The Vectura unit load stacker crane is a flexible and modular design concept which allows our customers to quickly configure the crane and ASRS to their specific application. Additionally, the flexibility of the Vectura concept means that the crane can act as a carrying platform for almost any type of product, and the accuracy of the positioning system means products can be picked and placed extremely precisely.

Single Mast vs. Double Mast

Projects that are "outside the box" are always extra challenging, but the strength, speed, flexibility, and accuracy of the single mast Vectura crane makes it capable of carrying heavy loads at high speeds in applications where our competitors are forced to use double mast cranes. For example, in one application utilizing 11 cranes, each at 43 meters high, we were the only crane bidder that could offer single mast cranes. There are many advantages of using a single mast crane versus a double mast crane, but some of the obvious advantages include:

- Reduction in total cost of the project

- More dynamic performance, meaning the system will move faster and with greater ease

- A lighter system creates less energy consumption, saving money down the road

Of course, sometimes we are forced to use a double mast solution due to size, shape, and/or weight of the load. An example of a double mast application is the solution we provided for Larson Boats in Minnesota. We were required to store and retrieve large boats, which didn't allow us to use a smaller, single mast system. We have also done several applications that handled car bodies and large truck cabins.

One such system used a Vectura double mast crane to place painted car bodies precisely on location pins within a rack; there were no fixtures. The Vectura position accuracy allowed the car bodies to be handled directly on specific hard points such as the jack positions. The applications needed for the automotive industry are always very challenging due to extreme quality standards and high uptime, but despite the difficulties, Swisslog has always managed to create effective solutions for our clients, regardless of the challenges or the client's industry. ---

About the Swisslog-Accalon Technology Center

The Swisslog Technology Center offers our cranes and conveyors to selected integrators worldwide. This partnership combines our experience and state-of-the-art products with our partners' knowledge of client systems and local conditions. We feel this business model is very successful, and jointly we strive to satisfy our end-customers.

Comments

Material Handling says:

8/28/2018 10:08 AM

Flexibility in crane systems is most required as it helps in moving of storage materials efficiently.

New & Used Warehouse Equipment says:

8/28/2018 10:08 AM

As technology gets better, automated storage and retrieval systems can do more and more. The flexibility that they now offer is incredible.

Rahul Karne says:

8/28/2018 10:08 AM

Pls contact regarding requirement of stacker crane 0091 9822444466

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.