The New Differentiator in Warehouse Software Isn't New

Damir Kantardzic | 02 July 2013

As customers, we all think we know what we want—especially when it comes to products.

It’s claimed that Henry Ford, inventor of the Model T car, said about his customers, "If I had asked people what they wanted, they would have said faster horses." This quote is often used to draw a line in the sand between two schools of thought when it comes to innovation:

- Innovation is best via responding to customers’ input

- Innovation should be independent of the customer to offer a product or service that customers might not yet know they need.

Innovation in any industry drives success and progress—including the material handling industry. In the past, warehouse and distribution products and services fell into two camps—material handling equipment and warehouse software. By understanding market trends and customer needs, companies soon found it advantageous to offer both hardware and software.

This holistic approach gave those vendors an innovative and unique selling proposition: the ability to implement end-to-end warehouse systems. In the early 90s, Bastian (then called Bastian Material Handling) focused mainly on material handling equipment, but quickly realized that warehousing software was becoming a key component of the business and that the hardware was becoming more of a commodity. This insight resulted from understanding what our customers needed to best meet their business requirements, challenges and future growth.

How a Customer Challenge Sparked Innovation

One of our customers exemplifies how a need progressed into an innovation. The customer needed to use carousels in conjunction with shelving and tie it all together with a conveyor system. However, they faced a major challenge: To make it work, they had to purchase at least five different software packages – a warehouse management system, carousel software and controls, and conveyor software and controls.

On top of that, the software applications would need to interface with one another. Making things even more complicated, the customer had future plans that involved additional automation. It seemed they would be adding one vendor after another. After consulting with the customer, we suggested an all-in-one warehouse software solution that would include the hardware, a warehouse control system and a warehouse management system.

This strategy offered several advantages:

- Support was provided from a single source.

- Interfaces between different software packages were not necessary, thus eliminating communication breakdowns, slowdowns and difficulties of passing business logic and decisions from one package to another.

- Integration of hardware and software was much simpler since the controls and software were completed by one team.

- An integrated WCS and WMS solution meant no complex synchronization of multiple systems, reducing the potential for hardware failures.

- Access to hardware status within the WMS allowed for near real-time decision-making during planning and waving of the work.

- The integrated system offered improved and accurate productivity analysis and reporting.

- Increased expansion opportunities as the software system provided the ability to switch out or add new hardware components to the system.

The advantages that were important back then prove even more important and relevant today. The customer saw an immediate increase in processing speed and order accuracy that exceeded their expectations. Additionally, the customer had to make only one phone call to receive instant technical support.

Warehouse Software Innovation Drives Growth

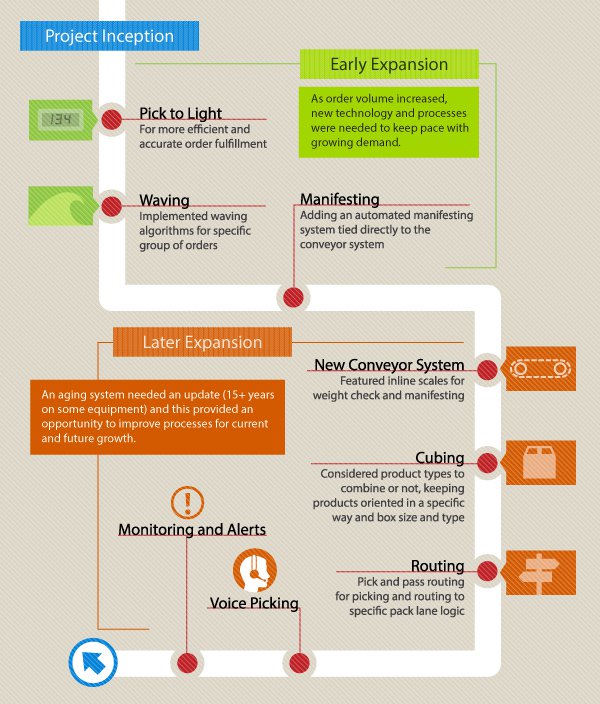

Over time, the customer quickly discovered that new initiatives were much easier to implement. The integrated system proved very useful, especially for projects such as waving and planning, where having direct insight to status of material handling equipment provided the ability to build very intelligent waving algorithms.

The early expansion was smaller than the later one, in which Bastian overhauled the entire conveyor system while still maintaining daily operations. Thanks in part to the integrated warehouse software system, the customer could perform such an overhaul while keeping the same software in place.  Going forward, the customer has many options and possibilities to enhance their operations. With new innovations such as Perfect Pick and other goods to person order fulfillment technologies, they are positioned to continue evolving their system even further thanks to an integrated warehouse software solution. Innovation ultimately serves the purpose of benefiting customers and moving forward in terms of technology, processes and ideas.

Going forward, the customer has many options and possibilities to enhance their operations. With new innovations such as Perfect Pick and other goods to person order fulfillment technologies, they are positioned to continue evolving their system even further thanks to an integrated warehouse software solution. Innovation ultimately serves the purpose of benefiting customers and moving forward in terms of technology, processes and ideas.

In the material handling world, we have been thrilled to help drive new concepts in WMS and WCS integration that allow our customers to achieve their goals, and we look forward to what future needs will drive changes in the industry.

Comments

Jason Morin says:

8/28/2018 10:08 AM

Interesting story. I fully appreciate the complexity and cost of integrating multiple systems as well as the challenges of bolting on additional systems in the future. It can be a nightmare.

The only argument I would raise against a fully integrated system is this: am I sacrificing best-of-breed WMS for the advantages of a fully integrated WMS/WCS/etc. package? Not all WMS packages are created equal and do not have the same functionality/feature/flexibility. As long as the client has fully vetted the WMS and feels it meets 95% of its needs, then a fully integrated package is the optimal route.

Damir Kantardzic says:

8/28/2018 10:08 AM

Thanks for the comment, and I agree with you: As long as the WMS portion meets the customer’s requirements, an integrated system can be a great opportunity.

SPS Chauhan says:

8/28/2018 10:08 AM

Great Article Damir. In India as well as we see project complexities I can relate to this article. We are moving more and more to Integrated Systems.

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.