The Importance of Installation Drawings for Your Material Handling System

Andrew Stockton | 15 September 2017

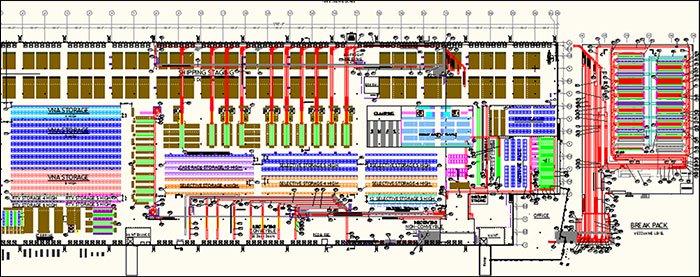

Detailed material handling system installation drawings lead to successful projects.

Material handling system drawings are a key tool when proposing a new system to a customer or vendor, so if they don’t make sense, it can hinder proposal discussions and the final outcome of the system installation. But once the proposal stage is complete and the job has begun, where do your drawings go from there? Do you start on finishing your building model? Do you start on the final layout drawings of the system? Or do you start on the details? There can be many levels to installation drawings (mechanical, ceiling support, air piping). These drawings need to be conveyed in a way that the person in the field completely understands the thought process of the person who drew them. In other words, the person creating the system installation drawings should assume the person installing the system is a rookie, brand new to installing material handling systems.

Successful System Installation Drawings

Building Model

To have successful drawings, you first need to have an accurate building model with everything dimensioned that could affect installations. If you don’t have an accurate building model, your design and budget could take a hit. You need to dimension all columns, paths or egress, building expansion joints, building joists, etc.

Creating the Final Layout

Once you have you building design, your next step is to complete a final layout. The final layout should provide the overall mechanical layout as well as any side elevations. I like installation on D size drawings, but sometimes a plotter is not available. If this is the case, the person creating the drawing should take note to scale the drawing properly if the drawing recipient will be printing less than D size.

Drawing Standards

Besides the installation crew needing quality drawings, it is also important that the team creating the drawings be on the same page with one another. Having standard drawing practices across a company creates efficiency. It is also important to have drawing standards so as your company grows and wins more and/or larger projects, multiple people can work on the same drawings without confusion.

Communication

The most difficult aspect of a large project and project team is ensuring good communication. Communication is the most important tool when drawing a system because if you have multiple people designing different conveyor lines there is always the possibility of the person crashing into another person’s conveyor. It is also important to standardize drawings because when you present your work to the customer, you do not want any discrepancies on how the drawings look (we want all the same text size, same dimensioning height, and same font).

As a company grows, you must make changes to accommodate the growth while maintaining standards for your installation drawings. Having a clear guide to detail software, formats, timelines, etc. will allow your team to efficiently create detailed, accurate drawings, which equates to success for you and the end customer.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.