Simulation or Animation – What’s the Difference?

Marvin Logan | 10 January 2013

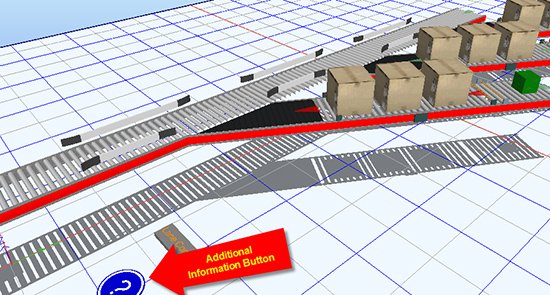

Simulation, animation, they’re basically the same thing, right? With the graphic capabilities of some simulation software packages, such as Demo 3D, it’s easy to see why people think these are synonyms. In reality, an animation is a pretty moving picture that can be used to help demonstrate to customers the flow and key design features of a system.

With Demo 3D, what looks like an animation, is really so much more. Demo 3D is one software package offered by Emulate 3D. It allows the user to build a model that is impressive--both visually and technically. I'm guessing you might be thinking "Wow that's great, but how does it work?" Well, there are several ways you can get started with Demo 3D.

Want a basic demo of a conveyor system to help educate your customer?

You can quickly create a basic model to use during the sales process to help explain your solution with the help of the QuickStart elements. What are those? QuickStart elements are developed by Emulate 3D and provided with the Demo 3D software. They’re the building blocks of a model.

Within minutes, you can have cartons moving on conveyors, forklifts moving pallets, even building components like mezzanines, stairs, and walls can be added. These building blocks aren’t just pretty – they’re smart too. They come with built-in logic that can be used to demonstrate accumulation, merges, and transfers without a lot of additional programming.

Want a more complex system to test logic and system throughput?

Demo 3D has a sample catalog full of sensors, conveyors, transfers, and other items that are graphic images without any programming. That means that you’re in charge of creating all of the logic that will move the loads through the system. It gives you a chance to customize everything, including how you write the logic.

You have three different ways to create the logic:

- Quick Logic, which is predefined blocks you arrange to create the logic you need.

- Script, which allows you to script the logic using Jscript.

- Ladder Logic, which allows you to use ladder logic to program the logic.

Each one is useful, but with my background I prefer to use the Script. Controls engineers may prefer the ladder logic option, while the Quick Logic option is great when you’re just learning and don’t have any experience with programming.

How you decide to use Demo 3D is up to you. It’s a dynamic tool that can be used in many different markets for a variety of things. The best part of Demo 3D? The support team! If you’re ever stuck on a problem and can’t figure it out, the support team at Emulate 3D is there to help. They go above and beyond to make sure you can get your model working and help you understand the software features.

Marvin Logan is the Vice President of Consulting and Integration at Bastian Solutions. After graduating from Purdue University, Marvin started his career as an industrial engineer and quickly moved into management. He has had roles as a distribution system manager, operations manager, director of engineering, director of distribution, and vice president of distribution for several leading companies.

Comments

E. R. Schatzman says:

8/28/2018 10:08 AM

Seems like ease of use of this software makes 3D necessary in today's competitive marketing. Good post Jesseca.

Jesseca Lyons says:

8/28/2018 10:08 AM

I agree. Being able to walk a customer through their solution in 3D used to be extremely difficult. With products like Demo 3D available, it's quickly becoming a necessity instead of a nicety.

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.