Robot EoAT Tool Changers: How & Where They Are Used

Mitch Stevens | 07 April 2020

On any given production line, a worker is typically required to complete a number of tasks using a variety of specialized tools. He or she completes a task with one tool, sets it down, picks up a new tool, and then completes the next task. The same process can be accomplished with robotic automation. A robot can be equipped with a tool changer that will allow it to change end effectors, either automatically or manually, thus letting it to complete a variety of tasks.

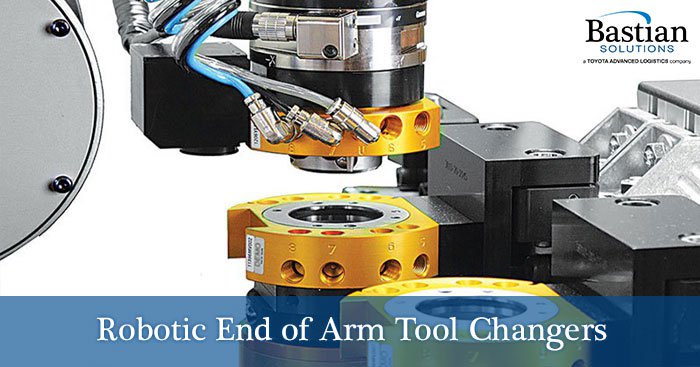

A robotic tool changer is a pneumatic coupling device that allows a robot to drop off and pick up different end effectors. Each tool changer consists of two components – the master plate and the tool plate. The master plate remains attached to the robot while a tooling plate is secured to each end effector tool. When completing a tool change, the robot moves to the tool stand, positions the current tool above the docking station and releases the tool. The robot then moves to the next tool’s docking station, connects the robot and tools plates, and picks up the new tool. The entire tool change process can be completed in a matter of a few seconds.

Most tool changers come standard with several pneumatic ports. However, tool changers can be outfitted with a variety of modules that allow electric, communication, pneumatic, and fluid connections to be completed. These modules allow for the robot to change between a variety of tools specific to a number of industrial applications.

Some typical tool changer applications include:

Machine Tending: A tool changer allows the robot to swap grippers between machine operations (OP10, OP20, etc.). It could also provide the flexibility to handle different product SKUs. This is typically completed via a tool change equipped with electric and pneumatic modules.

Palletizing: When palletizing products that require different handling techniques, a tool changer allows the robot to change between a vacuum tool, bag tool, clamp tool, and bottom-support tool. These connections are generally made with vacuum, pneumatic, and electric modules. More complex tools may require Ethernet and servo modules.

Assembly: Automated assembly tasks may be the most common application for tool changers. Using a tool changer, the robot can switch between various grippers, fastening tools, and sensors. Typically, these tools required electric and pneumatic modules.

Deburring: Robotic deburring applications are also one of the largest utilizers of tool changers. Deburring often requires different rotary tools and bits in order to effectively remove burrs from edges, corners, and holes. Often times, these tools only require the base tool changer without any additional modules.

Dispensing: Adding a tool changer to a robot in a dispensing application allows the robot to complete part handling (load/unload) between dispensing operations.

Welding: Similar to dispensing, adding a tool changer allows the robot to complete part handling between welding operations.

If you would like to learn more or have a robotic application that you would like us to look at, please reach out to us at Bastian Solutions.

Mitch is a field application engineer for Bastian Solutions' robotics division. He has Bachelor of Science degree in mechanical engineering from the University of Illinois. As an application engineer, he helps Bastian Solutions’ customers find the right robotic solution for a variety of applications, some of which include palletizing, machine tending, packaging and assembly.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.