Rethinking DC Packing Automation for E-fulfillment

Chris Bratten | 16 June 2021

Pick, pack and ship is fairly straightforward but with increasing pressures to process orders faster and faster, these tasks can give your company a competitive edge.

When I’m looking at a customer’s distribution center, there are certain indicators I look for to try to find improvement opportunities. For a company that processes ecommerce orders, pick totes are at the top of that list.

While they’re sometimes necessary, they’re often a red flag for underlying operational inefficiencies. However, these inefficiencies are easily remedied through a combination of process flow updates and new automation. These projects often have a fantastic ROI, paying back the initial investment in one to two years. To top it off, they’re easy choices for our customers to implement.

Pick, Pack and Ship

When a new warehouse goes live, it’s inevitable that they will choose the simplest process that fits their current needs. Most warehouses fulfill orders through some sort of pick, pack and ship process. Items are picked in dedicated picking areas and placed intro a generic container – usually a tote – and sent downstream to a pack area.

As simple and straightforward as the “packing process” sounds, operators fulfill numerous additional functions as part of this task, including:

- Inspecting the order to confirm that the correct items were picked.

- Building a shipping container from flat corrugated sheets.

- Transferring items to the shipping container.

- Inserting dunnage and packing materials to secure the package.

- Printing out and inserting any order documentation or promotional materials.

These functions take time. It can take operators anywhere from 30 seconds to several minutes to pack a single order!

Packing Automation Opportunities

Packing is often one of the most labor-intensive processes in a distribution facility. However, there is good news. Advanced automation technology can manage and transform traditional pack processes through simple changes in machinery and process flow.

Build Boxes – On demand packaging equipment by Packsize can build boxes of any shape and size. They can also produce and insert order documentation up front.

Pick to Ship – Picking operators can pick directly to the shipping box instead of bins, reducing unnecessary steps.

In-line Technology – In-line weight scales validate the contents of the box with incredible accuracy and flag boxes that may require review.

Shipment Protection – Dunnage insertion stations and automatic tapers fill and seal boxes automatically.

Labels – Print and apply labelers apply shipping labels quickly and accurately through a manifest engine powered by the Exacta software.

Unlocking Opportunity with Automation

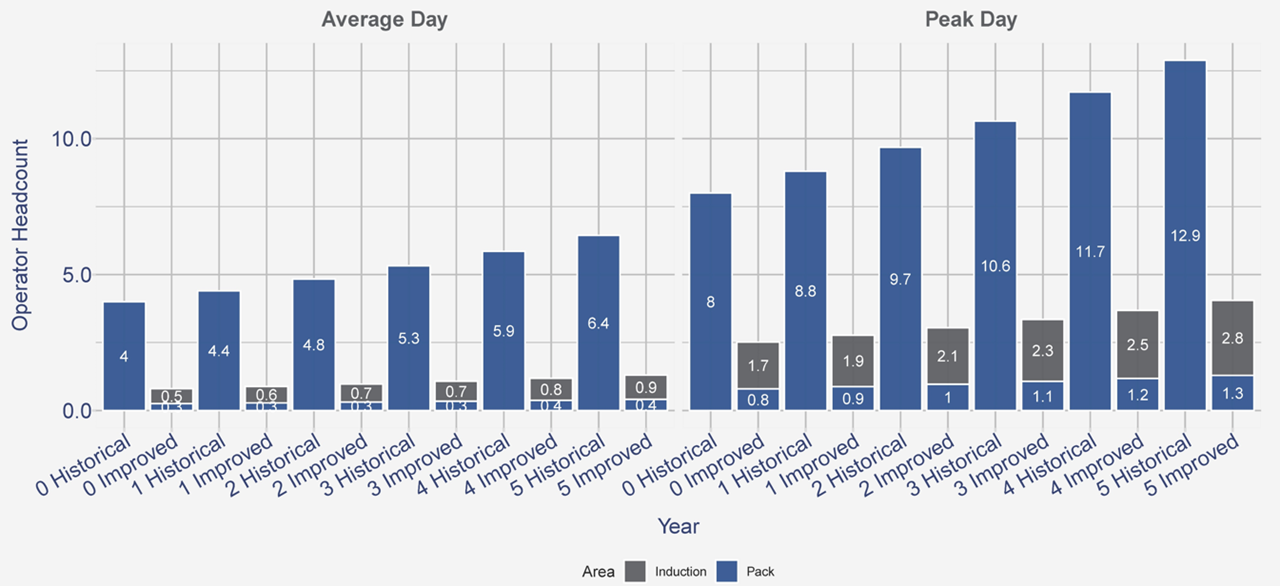

In a recent example, Bastian Solutions worked with a cutlery distributor to improve their outbound order fulfillment methods. They had always picked to totes and utilized a pack process to move products from the totes to shipping boxes. However, as ecommerce orders continued to grow, the pack process became a bottleneck. On peak days, they had eight full time employees packing out orders.

Changing the process flow allowed them to cut this down to three operators on a peak day. Two operators building boxes on the front end of the process and one operating an in-line dunnage insertion and carton sealer. All picked cartons passed over a weight scale that validated that the order weight matched the expected carton weight.

Not only did this solution reduce labor, but it also increased throughput, allowing them to grow as expected for another five years with no capacity constraints. This simple project had a fantastic ROI.

Costs were minimal because the new equipment was easy to integrate into the existing process flow and major facility construction was avoided. The most challenging part was figuring out what to do with all of the new floor space that we freed up!

Smarter and More Efficient Operations

Reducing touches is key to most improvement initiatives. Labor efficiency and process reliability increase the fewer times your operators touch products or orders. Today’s advanced technology makes cutting out totes a fantastic way to reduce touches. Think about it, no one ships products in totes – why pick into them when you don’t have to? Bastian Solutions engineers can help you assess operations, determine the best technology and configuration, and create a resilient system that maximizes throughput, efficiency and ROI, even during market changes.

Chris is a Logistics Consulting Manager at Bastian Solutions, based in Louisville, Kentucky. He has a Bachelor of Science in Mechanical Engineering from Rose-Hulman Institute of Technology and a MSME from Purdue University. Since starting with Bastian, Chris has developed and maintained strong relationships with his clients; designing solutions and supporting system integrations.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.