Options Available with AS/RS Technology

Aaron Jones | 05 March 2010

In my first article, I discussed a method of quickly testing the applicability of a particular solution without investing a great deal of time or energy in investigating the concept. This “first blush” approach has saved me countless consulting hours by avoiding alternatives that will not pass the test of selection. This, in turn, has allowed me to spend more time on the eligible candidates that hold more promise. But what are the alternatives when it comes to implementing an AS/RS?

It turns out that the variations in this family of technology are far greater than one might expect. Since the introduction of this class of handling equipment in the 1960’s, many derivations have resulted that addressed unique challenges or special conditions. Today, the systems that provide storage buffering are numerous, unique, and continuously evolving. To paraphrase God, Himself, “…In the beginning…”, man was seeking a way to eliminate the damage, misplacement and pilferage that came with human handling of loads in the warehouse.

Keep in mind that in those early days, the concept of warehouse control was based on rather antiquated, batch oriented information systems, and real time updates of where and when inventory was placed was practically non-existent. Also not present was the concept of Just-In-Time flow control of inventory through the supply chain. In fact, the term “supply chain” wasn’t really heard by this writer until the mid 80’s, and then only a token reference was made to the need for vendors to set up across the street from their customers to effectively shorten the chain.

To counter this in the 60’s, the AS/RS system was introduced as a means of eliminating the fork lift truck and the errors induce with manual handling. These systems were built to hold unit loads of higher value product until needed on the assembly line. This allowed better control of the product from a theft and damage point of view, and because the inventory was in a known location, also aided in control – especially in MRP based systems where forecast and reorder points were able to work against better information about on-hand status. This article will discuss some of the options available to the designer for Unit Load AS/RS Systems. Mini and Micro Load systems will be discussed in the next article.

As the name suggests, these systems are designed to buffer a unit load between the supply and consuming operations. Typically, a unit load will be a single pallet of one SKU. Unit loads stereotypically are on GMA or CHEP pallets with a footprint of about 40” x 48” and weigh about 2,200lbs (1,000 kg – 1 metric ton). That generalization is dangerous, because Unit Load refers more the characteristics of application, than it does load dimensions and weight.

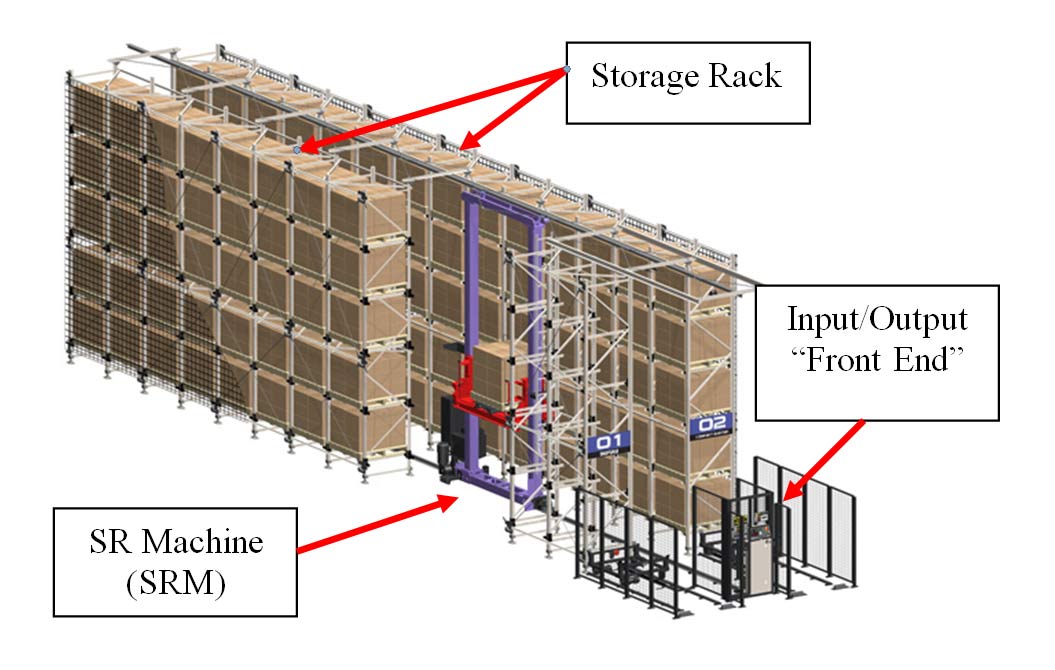

Typically, Unit load systems describe a process where inbound loads are unitized by the inbound supplier, stored until needed in the Unit Load buffer, and then brought out for consumption as a Unit load. These are also referred to as full load in, full load out type of systems. The first systems of this type were also called Crane-In-Aisle systems, referring to the Storage and Retrieval Machine that was in the aisle. Loads were stored 1 load deep in the rack systems adjacent to the aisle. The single deep system (a modern version of this is shown at right) has several unique features that lend to its justification:

Benefits of Single Deep AS/R system designs:

- Floorspace utilization is greater than with even narrow aisle fork lift warehouses.

- These systems can store at heights up to 50 meters – although zoning and local restrictions may limit the system’s height.

- A single SRM can produce the same load handling activity as about 3-4 fork lift operators on powered trucks.

- Accuracy is nearly perfect because of the inherent checking that is done on each step of the process of receiving, buffering, and retrieval.

- These systems are inherently safe. No operator ergonomics or operational hazards are presented when properly applied.

Additional features of the single deep system include the ability to access any load that is in the buffer as the next thing the SRM will retrieve. This significantly improves the responsiveness of the system to react to unplanned demands by the consuming process.

Evolution of the Multi-Deep AS/R system design

One of the considerations in design of an AS/R system is the nature of the inventory, and the type of buffering that will correctly serve the consuming process. With a single deep design, a system where a large number of loads is to be stored may result in a system that is very long, or must have multiple aisles in order to accommodate the number of loads to be stored. If length or height is restricted, multiple aisles may be the only solution. If throughput is relatively low, a multi-aisle system may result in cranes that are severely underutilized from a Technical Utilization point of view (see Article 1).

A solution to this problem may be found in the use of what is called a multi-deep AS/R system design. With these systems, the racks on either side of the aisle will hold 2 or more unit loads. The most common of these is the double deep system, but there are products available that store 3 deep and even deeper. The Deeper systems are referred to as Deep Lane systems, and we will get to those in a few paragraphs.

For a multi-deep system to work, however, one of two things needs to be in the mix of requirements: (1) the system is designed with the capacity to “shuttle” the front load to give access to the back load(s), or (2) the inventory is such that a LIFO mode of control can be employed when accessing to loads of the same SKU in a given opening. There are some good emerging exceptions to the above, but for now, let’s consider these. With this class of system, if there is no commonality of SKU’s, there is a 50% chance that the last load stored in a multi-deep lane will block access to load(s) behind it. In a triple deep system, the probability rises to 66% that one or more loads will need to be moved to get to the requested load.

With this class of system, if there is no commonality of SKU’s, there is a 50% chance that the last load stored in a multi-deep lane will block access to load(s) behind it. In a triple deep system, the probability rises to 66% that one or more loads will need to be moved to get to the requested load.

This movement of a load to access a rearward load is called a “Shuffle” Control systems can help to mitigate this, but rarely are multi-deep systems applied in applications where SKU diversity is high. In fact, a pragmatic rule of thumb (PROT) is that you need to have a pallet to SKU ratio of about 6 before it makes sense to consider a multi-deep solution. This is 6 pallets of a given SKU/Lot. This maximizes the probability of storing two identical loads from the same lot in a given opening. Going beyond 6 is also good, but 6 seems to be the point of diminishing returns.

Benefits of Multi Deep AS/R system designs:

- Floorspace utilization is even greater than single deep designs.

- These systems can also store at heights up to 50 meters – although zoning and local restrictions may limit the system’s height.

- A tall, single SRM can produce the same load handling activity as about 3-4 fork lift operators on powered trucks operating in a warehouse large enough to handle the same number of loads.

- Accuracy is nearly perfect because of the inherent checking that is done on each step of the process of receiving, buffering, and retrieval.

- These systems are inherently safe. No operator ergonomics or operational hazards are presented when properly applied.

The use of multi-deep designs provides for smaller system footprints, and ultimately lower costs per load position of storage. If shuffling of loads can be avoided through LIFO methods and consideration of the SKU diversity, these systems are highly productive.

One effective method of mitigating the shuffling penalty is to use a SRM that has dual load handling devices. This allows the SRM to retrieve the blocking load with the first device, and then retrieve the required load with the second. The first load is then restored before the required load is returned to the Input/Output stations. This, of course, adds cost to the equation, but is quicker than moving the load to another storage position and returning for the required load.

Deep Lane Solutions

Deep lane solutions are not a new innovation. They were first introduced in the late 70’s as a way of buffering the output of production processes that produced many loads of the same SKU before switching to a different product. There was little need for random access to any load in storage, but there was a need to automatically handle the loads and hold them until quarantine factors were approved.

Today, deep lane systems are being used to accommodate the large flow bursts that seem to come with today’s supply chain. Overseas container shipments often produce high transaction volumes for storage until redistribution can be scheduled. This is a labor intensive operation, and in the interests of reducing labor content while simultaneously minimizing capital investment, and in consideration of some novel application concepts that take advantage of the design, deep lane solutions have enjoyed a rebirth of popularity.  The deep lane system concept has much of the same characteristics as the multi-deep, but the equipment is slightly different, and the SKU density PROT is much higher, typically ranging from 15 or higher with a rather tight standard deviation, or a demonstrated exponential distribution of lot size.

The deep lane system concept has much of the same characteristics as the multi-deep, but the equipment is slightly different, and the SKU density PROT is much higher, typically ranging from 15 or higher with a rather tight standard deviation, or a demonstrated exponential distribution of lot size.

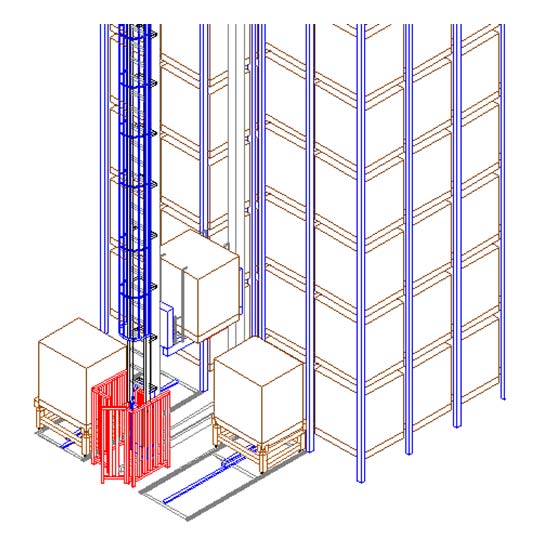

The primary difference is the length of the opening in which the loads are stored. Typically, these lanes can range from a few loads deep to up to 10 or 15 loads, depending on the application. The SRM is equipped with a special shuttle (also referred to as a Mole or Satellite) that leaves the SRM to transport the load to and from the storage location. These special shuttles are often tethered back to the SRM, or battery operated when not onboard the SRM. The advantage of the latter is the ability to develop an application where the SRM can actually do other things while the shuttle is moving to or from a far end storage position.

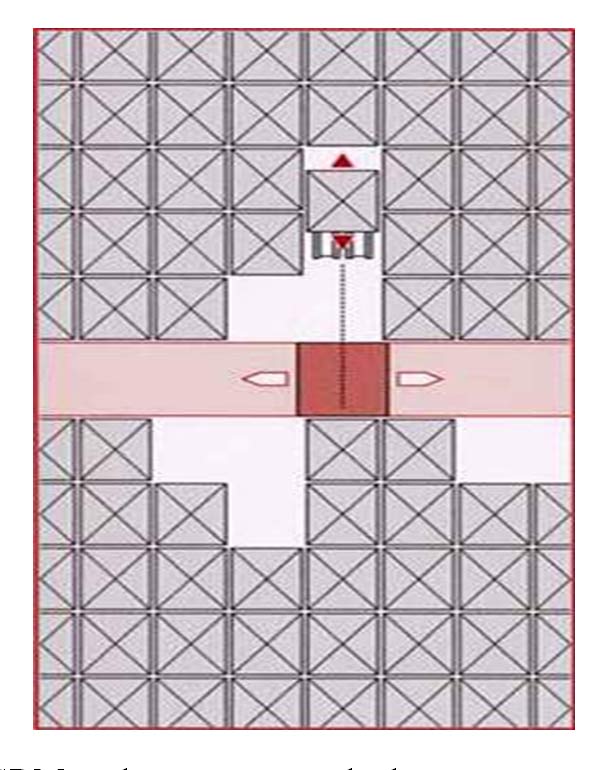

Decoupled Deep Lane Solutions

An emerging solution that has a lot of interest is a variation on the deep lane solution. It goes one step further by removing the SRM from the aisle and replacing it with transfer carts at each storage level. This provides a much higher throughput, because it decouples the SRM’s X, Y and Z motions, allowing them to operate independently. The X and Z axis of travel are serviced by the transfer car at each level, and the Y motion is serviced by a load lift at the end of the aisle. Multiple load lifts can be deployed to bump throughput, or simplify the applications (i.e. one for input and one for output). This not only promises higher throughput, but higher system availability. The failure of 1 component is far less likely to disable the system than in other designs.

Benefits of Deep Lane AS/R system designs:

- Floorspace utilization is Highest of all AS/RS concepts currently in play.

- These systems can also store at heights up to 50 meters – although zoning and local restrictions may limit the system’s height.

- Accuracy is nearly perfect because of the inherent checking that is done on each step of the process of receiving, buffering, and retrieval.

- These systems are inherently safe. No operator ergonomics or operational hazards are presented when properly applied.

Other Alternative Developments

Many derivations of the stereotypical AS/RS system have been developed. All of these were conceived to address either a limitation of the basic designs discussed so far, or to provide a unique capability that was more process specific. For example, consider the situation where you must buffer a load for a period of time for the process to complete (i.e. curing or aging). The throughput is relatively low, but the height and length restrictions are severe.

A solution often used in this situation was a system where the crane was transferred to other aisle – instead of merely putting a significantly underutilized crane in each of several shorter aisles. While this worked, the complexity of the design, the space for a crane transfer vehicle, and the interface to the system all contributed to a less than desirable solution. While many have been built in this manner, and illustration of innovation comes from Germany where the crane changes aisles by itself – much the same as a VNA truck would change aisles in a conventional warehouse. The cranes generally run on a rail. That rail is straight and terminates at the end of each aisle.  By putting articulating wheels on the crane, curved rails and special rail switches allow the crane(s) to leave the aisle on the rail and travel to other aisles without the need for the transfer car. Along the way, they have the opportunity to interface with the P&D stations. While not inexpensive, it is lower cost than multiple cranes, faster and much more design and storage efficient than a transfer car based solution. It keys on the concept that there are only 3 dimensions of motion, X, Y, and Z, but how they are oriented in a polar perspective is up to the inventor.

By putting articulating wheels on the crane, curved rails and special rail switches allow the crane(s) to leave the aisle on the rail and travel to other aisles without the need for the transfer car. Along the way, they have the opportunity to interface with the P&D stations. While not inexpensive, it is lower cost than multiple cranes, faster and much more design and storage efficient than a transfer car based solution. It keys on the concept that there are only 3 dimensions of motion, X, Y, and Z, but how they are oriented in a polar perspective is up to the inventor.

In summary, the unit load AS/R system is dominantly applied for “full load in” – “full load out” types of applications. That is not an exclusive rule, but is fairly common. The most basic of designs is the single deep crane-in-aisle configuration, but that is becoming the exception as technology, software and creativity take over to add speed and flexibility to the other types of systems discussed in this article. The reasons AS/R systems are being used for this application is control, elimination of variance/cost adding labor, and space utilization.

Whether you use manual methods or automation like the AS/RS, it is in place to buffer the flow of material between the supplier and the consumer. And remember, there are only three things you can do to a load: move it in the X direction; move it in the Y direction or move it in the Z direction (four if you count losing it, which just doesn’t happen in an AS/RS).

President & CEO of Bastian Solutions.

Comments

Boainfo says:

8/28/2018 10:07 AM

Boainfo...

[...]Options Available with ASRS Technology | The Material Handling Blog[...]...

Sea Shipping Containers says:

8/28/2018 10:07 AM

Sea Shipping Containers...

[...]Options Available with ASRS Technology | The Material Handling Blog[...]...

Enter here says:

8/28/2018 10:07 AM

I have implemented your blog for quite a while and must claim that this time a person hit the actual nail together with precision as never, I've almost exactly the same thought as well as ideals as you have, keep coming with gold content like this you'll also find a follower forever!

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.