New Design Tools for the Creative Engineer

Bill Bastian II | 16 February 2012

With the pace of business continually accelerating, it is nice to see the selection of new engineering design tools rising to the occasion. Although there is no substitute for sound engineering fundamentals, these tools can help engage an engineer's creativity by speeding up the iterative design process. The first noteworthy tool is a hand-held 3-D scanner, which creates a 3-D model of most any object.

Real time surfacing shows the object on your lap top throughout the scanning process. Resolutions can provide accuracies down the sub-millimeter level. This tool enables the creative engineer to take a collection of existing physical objects and quickly build 3-D CAD models for their manipulation or reproduction. The second time saving tool is a 3-D printer. The price curve continues to drop (now starting under $15,000), while the functionality continues to expand. Models can now be produced in 24-bit color.

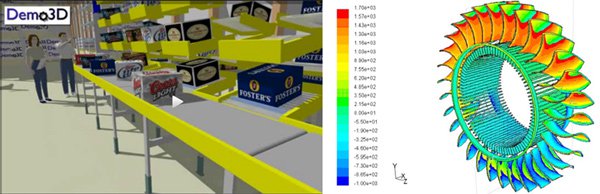

Three-dimensional printing allows several inexpensive prototypes to be made and tested quickly. The plastics being used are often good enough to test the product in a production environment. As 3-D printing advances, one of its core strengths is the ability to make a single complex part that would normally require several sub-assemblies with fasteners. This translates to reduced weight (no fasteners) and reduced labor (no assembly required). And finally, simulation tool advancements allow more virtual testing well before a physical prototype has to be constructed. Simulators can model the physical kinetic reactions between different objects, which is very helpful in material handling product flow analysis.

Three-dimensional modeling tools and simulators provide finite element analysis (FEA) for structural strength, thermal characteristics, and vibrational analysis. This allows the creative engineer to go through several rapid virtual design iterations before committing the resources for a physical prototype. It is amazing what these new tools can do for a creative engineer developing new products. And to think that just few short years ago I thought I was pretty cool with a scientific calculator.

References: PE Magazine. January / February. "Back to the Future" Fast Company Magazine. February. "MakerBot's 3-D Printers"

Bill began his career at Bastian Solutions back in 1987. As an engineer and entrepreneur, he enjoyed helping with the growth of his family-based business. During his tenure, he was involved with most all material handling technologies: robotics, AS/RS, sortation, Warehouse Management Systems (WMS), Warehouse Control Systems (WCS), RFID, Pick to Light, Pick to Display, etc. While President of Bastian Solutions, he provided the vision for where the company would go in the future, providing value to customers and a great working environment for employees. Bill retired from Bastian Solutions in 2019, after the company was purchased by Toyota Advanced Logistics North America.

Comments

Material Handling says:

8/28/2018 10:08 AM

3D scanners and printers are useful when large objects are to be scanned or their printouts are taken. Warehouse deals with large materials and objects which needs big scanners and printers at the warehouse. These are very useful tools in a warehouse.

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.