Navigating Fire Suppression Requirements in Canada for Material Handling Automation Equipment

Kevin Auger | 4 September 2024

Fire safety is a critical concern in warehouse, manufacturing, and distribution facilities due to the potential for significant damage and loss. In Canada, stringent regulations around fire suppression systems often surprise customers looking to install material handling automation equipment. These regulations particularly impact facilities handling flammable products such as textiles, fragrances, and aerosols.

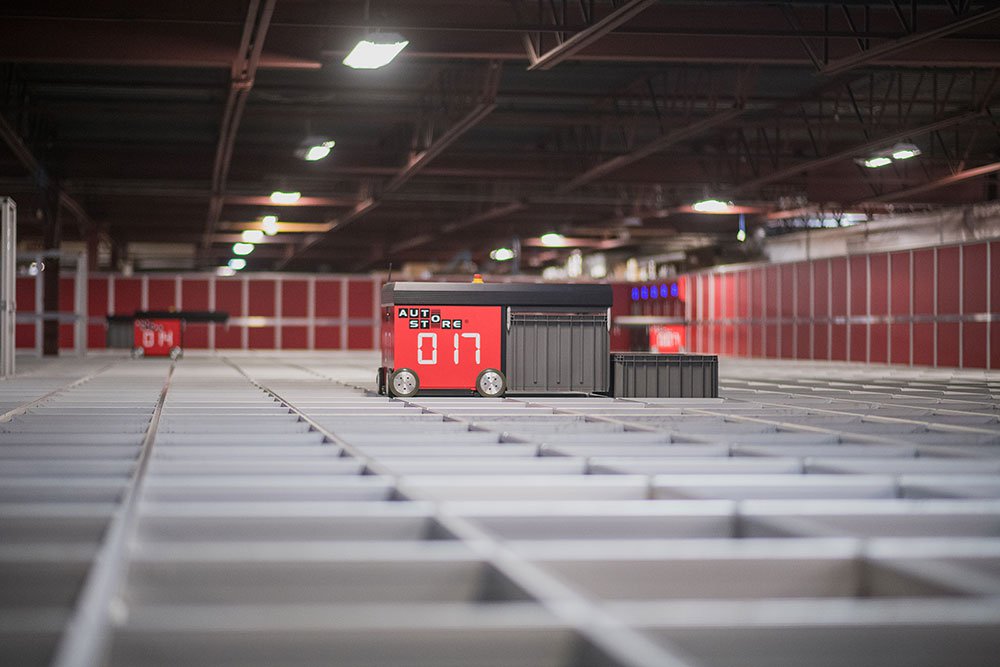

Automated bin systems, for example, pose a unique risk. Stacks of plastic bins can be challenging to suppress in a fire because the plastic is highly flammable and can spread the fire quickly. However, some systems, like AutoStore, have a strong safety record with no reported fire incidents, highlighting the importance of choosing the right technology.

Due to the fact that this type of automation falls outside of the National Fire Code of Canada 2020 (NFC 2020), an alternative solution is required for fire suppression. The FM Global Datasheet (Protection for Automatic Storage and Retrieval Systems) covers the unique fire suppression requirements for this type of technology. The NFC 2020 oversees all of Canada, but each province and municipality has their own set of Fire Codes (ex. 2023 Ontario Fire Code). . Understanding how these regulations affect your organization can help you better prepare for a material handling automation installation in your warehouse or distribution center. By asking the right questions and engaging with knowledgeable partners, you can navigate the complexities of fire suppression requirements in Canada and make your project a success.

Key Considerations for Fire Suppression in Automation Projects

When planning a material handling automation project, addressing several critical questions to ensure compliance with fire suppression requirements and avoid unforeseen challenges is essential. Partnering with a local material handling automation integrator can provide invaluable assistance in navigating these complexities. By addressing these concerns early on, you can streamline the approval process and secure the necessary endorsements from insurance providers, local authorities, and landlords. Here are three key questions to consider:

Question 1: Will your insurance company accept the material handling automation technology?

Insurance companies are crucial in approving fire suppression systems for material handling automation projects. Each insurance provider has its standards and requirements for fire safety, which can significantly impact your project. Understanding these standards is vital, as they can influence the type of fire suppression system you need and the overall design of your automation setup.

Consulting with your insurance provider early in the project is essential. You can ensure that the fire suppression systems you plan to install meet their requirements by involving them from the start. Failing to do so may result in additional costs, delays, or even the inability to secure necessary insurance coverage.

Question 2: Will the municipality accept this, and what are the requirements?

Local fire authorities and municipal regulations play a significant role in approving material handling automation projects. Municipalities can have varying responses and requirements based on their specific risk assessments and local fire codes. Understanding these differences is critical for ensuring compliance and avoiding project delays.

Engaging with local fire authorities early in planning is crucial to navigating municipal regulations effectively. This helps you understand your municipality's specific requirements and allows you to address any potential concerns proactively. Compliance with local regulations ensures that your project can proceed smoothly and without unexpected interruptions.

Question 3: If you lease your warehouse or building, will your landlord permit this project? Will their insurance cover it?

If you lease your building, your landlord also has a significant role in approving fire suppression systems. Landlords may have fire safety requirements and insurance coverage policies that could impact your project. Ensuring alignment between your project and the landlord's policies is crucial to avoid conflicts and ensure smooth project execution.

It is essential to verify that the landlord permits installing the proposed fire suppression system and that their insurance coverage is adequate. If the landlord’s insurance does not cover the required fire safety measures, you may need to negotiate additional coverage or explore alternative solutions. Ensuring all parties are on the same page helps prevent potential delays and complications.

By considering these fundamental questions and engaging with the relevant stakeholders early in the process, you can navigate the complexities of fire suppression requirements and ensure the successful implementation of your material handling automation project.

Bastian Solutions is Your Local Material Handling Automation Integrator

Bastian Solutions’ strong local presence in Canada positions us to support you through the complexities of fire suppression regulations effectively. We have established relationships with trusted third-party experts who can assist in navigating project approvals, ensuring that every aspect of your project meets regulatory standards. As an integrator, we take a consultative approach to each project, exploring various technologies to meet safety requirements and your automation goals with a brand agnostic perspective

Partnering with Bastian Solutions means having a knowledgeable local ally who can help you navigate the complexities of fire suppression regulations in Canada and ensure that your material handling automation project is safe and compliant.

Contact one of our engineers today to explore a material handling automation solution for your location.

Kevin Auger is a Canada Country Sales Manager at Bastian Solutions based in Montreal, Quebec, Canada. Featuring a background in engineering, Kevin has a Baccalauréat en génie de production automatisé from Université du Québec - Ecole de Technologie supérieure and a Diplôme d'étude collegial in industrial electronics from Cégep de l'Abitibi-Témiscamingue.

-

Kevin Auger est un directeur des ventes chez Bastian Solutions et travaille à Montréal, dans la province de Québec au Canada. Kevin possède de l’expérience en ingénierie et un Baccalauréat en génie de production automatisé de l’Université du Québec – École de Technologie supérieure, ainsi qu’un Diplôme d’études collégial en Électronique industrielle Du Cégep de l’Abitibi-Témiscamingue.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.