Mixed Load Palletizing: Can it be done?

Bastian Solutions | 15 July 2010

The simple answer is yes!

The good news is that this long talked about concept has been proven within the last few years. You can hardly be in business anymore without being impacted by the need to deliver only what your customer needs. The days of shipping excess are over and everyone is looking to eliminate waste in their supply chain process.

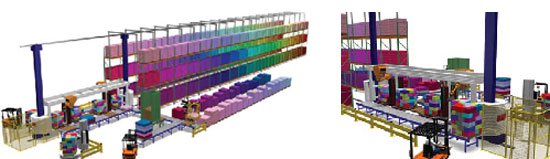

As an independent integrator, Bastian Solutions is a leader in mixed load palletizing. We have combined the strength and dexterity of palletizing robots, the power and flexibility of software algorithms, and our comprehensive understanding of order fulfillment and the warehouse environment to provide robust solutions for our customers. Depending on business factors, solutions do vary.

The basic flavors of mixed load palletizing are mixed layer palletizing, mixed case palletizing, or a combination of both. The technologies applied today to automate these processes are proven to be reliable and efficient. Whatever the mix of products, the goal is to efficiently build mixed load pallets that are stable. The algorithm decision making process can be easily modified to fit each customer’s unique requirements.

A recent example we included in the algorithm is to not put detergents on layers above food products. This eliminates the opportunity for contamination. Whatever business rules are currently in place for your process, they can be applied to the automation system and you are insured that the rules are consistently followed. Graphical operator interfaces are available so that loads can be seen as they are built.  One obstacle in the past was the control of the sequence of the boxes presented to the robot. This presented a problem when there was a shortage or a defect. The software solutions today are more dynamic in that they can re-evaluate the load building sequence on the fly and choose the optimal pattern if the planned sequence randomly changes or a product is omitted. In the dynamic world of supply chains, one thing is for certain. Product sizes and quantities required by your customers change frequently.

One obstacle in the past was the control of the sequence of the boxes presented to the robot. This presented a problem when there was a shortage or a defect. The software solutions today are more dynamic in that they can re-evaluate the load building sequence on the fly and choose the optimal pattern if the planned sequence randomly changes or a product is omitted. In the dynamic world of supply chains, one thing is for certain. Product sizes and quantities required by your customers change frequently.

Having the capability of efficiently and accurately building stable mixed loads will help insure that your customers receive the highest quality products. Bastian Solutions works closely with our customers to produce the right solution to meet their requirements.

Bastian Solutions, a Toyota Advanced Logistics company.

We are a trusted supply chain integration partner committed to providing our clients a competitive advantage by designing and delivering world-class distribution and production solutions.

Our people are the foundation of this commitment. Our collaborative culture promotes integrity, inclusion, and innovation providing opportunities to learn, grow, and make an impact. Since 1952, Bastian Solutions has grown from a small Midwest company into a global corporation with over 20 U.S. offices as well as international offices in Brazil, Canada, India, and Mexico.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.