Mini-Load ASRS: What Is It & Why Do You Need It?

Bastian Solutions | 24 January 2018

ASRS is the short way of saying “Automated Storage and Retrieval System.” Although these systems have been around for several years, many in warehousing facilities have not heard of it, and those who have might not exactly understand what it is or how it could benefit their operations.

When a technology is misunderstood, then generally there is resistance to the change, even if it is likely to provide improvements. Hopefully with a better understanding of what an ASRS system is and what it can do, you can effectively implement it as a solution in your order fulfillment operation.

What is a Mini-Load ASRS?

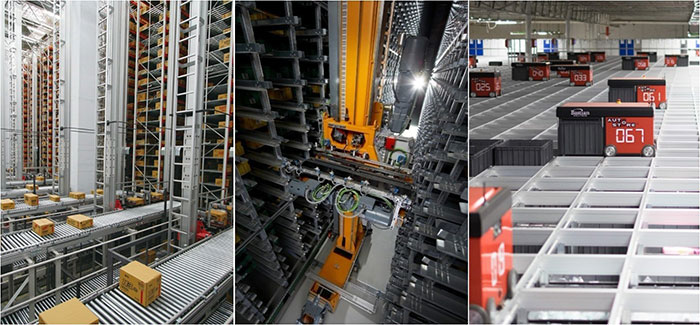

There are really two categories of ASRS; those include what is termed a “Unit Load” and “Mini Load”. Unit load ASRS refers to large format storage such as pallets and large crates whereas mini load, as the name suggests, refers to storage of smaller containers such as totes/tubs, cartons or trays. The focus of this article will be on the latter.

A mini-load ASRS comes in several forms, with each design having its pros and cons. A key function of an ASRS is to remove the need for warehouse staff to walk or travel to product storage locations as well as utilize available floor space to its maximum efficiency. This is achieved through a combination of dense storage and product extraction via shuttles, satellites or robots, which carry the cartons or totes from the storage location to a “station”. At a station, picking or replenishment occurs.

With certain ASRS, picking and replenishment can occur at the same stations which enables flexibility of operations. A good example of a type of technology which is capable of this is the AutoStore® robotic goods to person system. This technology, designed and manufactured in Norway, happens to be the densest storage system on the market, with the ability to scale up in size and throughput without the need of halting any existing operations. It is an extremely flexible solution with companies adopting this technology often starting off small and scaling up the system as business grows. The entry point into this technology is also extremely low, which makes it attractive for many companies looking for their first step into ASRS or even automation in general.

Mini-Load ASRS Usage

The adoption of advanced technologies such as AutoStore or other mini-load ASRS is often delayed, with larger companies generally the first to invest in these areas. That is understandable, large companies often have the financial means to justify investment in automation, but what about the smaller companies? Is it out of reach? Well, no actually. Many companies simply tend to be more conservative and apprehensive of taking the step into new technologies.

No matter what the size of the organization, a key way to justify any change to the operations is if there is a suitable Return on Investment (ROI) and if the technology makes sense. To determine if there is scope for change, some data analysis of existing operations is needed, which is one of Bastian Solutions’ strengths.

Being a system integrator, our experienced design teams and reach of technologies is unsurpassed, enabling us to offer the right solutions to our customers. If your existing operations pick from racking or shelving, then often there is a solution which can be tailored to make efficient use of the space available and reduce the amount of travel staff make to fulfill their warehousing duties.

Bastian Solutions can help by assessing the suitability of technologies on the market for existing operations, offer ROI calculations and work towards a common goal. This is done by offering the full circle solution including design, integration, installation all the way through to service and support.

Please visit our website and browse our solutions and case studies to learn more. Then contact us if you want more information on how we can help your business grow.

Bastian Solutions, a Toyota Advanced Logistics company.

We are a trusted supply chain integration partner committed to providing our clients a competitive advantage by designing and delivering world-class distribution and production solutions.

Our people are the foundation of this commitment. Our collaborative culture promotes integrity, inclusion, and innovation providing opportunities to learn, grow, and make an impact. Since 1952, Bastian Solutions has grown from a small Midwest company into a global corporation with over 20 U.S. offices as well as international offices in Brazil, Canada, India, and Mexico.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.