Microfulfillment Part 2: Pros and Cons

Greg Conner | 29 July 2020

The term “microfulfillment center” has quickly become one of the top buzzwords in material handling. But what is it and is investing in it the right decision for your supply chain?

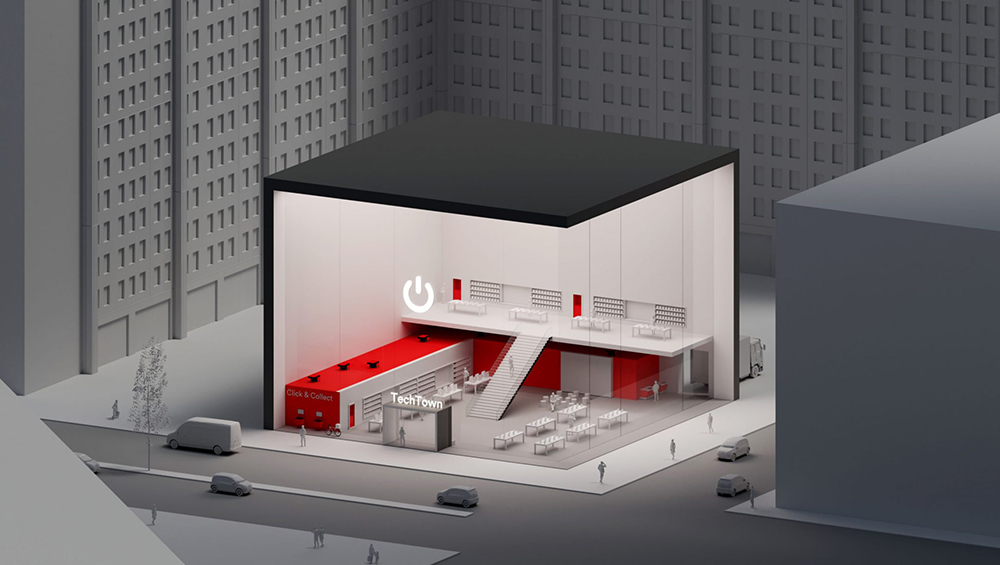

Let’s start with what a microfulfillment center is. Simply put, a microfulfillment center is the concept of utilizing small-scale distribution centers close to the consumer so to reduce shipping time. For example, as opposed to a retailer fulfilling online orders to customers in Manhattan from a large regional distribution center located in central Indiana, the retailer could utilize a microfulfillment center located somewhere in the greater New York City area and reduce the time it takes to reach those consumers from a few days to in some cases a matter of hours. More info and details are available in part one of this blog series.

So, is a microfulfillment center strategy correct for your supply chain? Let’s evaluate the pros and cons of microfulfillment centers.

Pros

- Improved Delivery Times

Shipping from microfulfillment centers should result in a reduction in transit time to the end customer. I stress “should” because efficiency gains only come if the correct software, automation equipment and operational procedures are in place. As many companies will attest, splitting inventory is no easy feat. That said, many companies are achieving same day delivery metrics through the utilization of microfulfillment centers.

- Improved Customer Satisfaction

Thanks to Amazon and their Prime program, customers are expecting to receive online orders faster and faster. The recipe is simple, ship the correct product to the correct customer within the same day or the very next day and your customers will love you. Through microfulfillment these delivery promises can be achieved which will result in increased customer satisfaction.

- Increased Sales

Study after study has shown that when price is not a factor, people will choice the company that get can fulfill their order the quickest. Companies that have invested in microfulfillment report significant increases in overall sales. The reverse argument can be made for companies that don’t invest in a microfulfillment center strategy.

- Better Process for Handling Returns

As most retailers will confess, returns are the Achilles heel of the supply chain. Historically, five to ten percent of in-store purchases are returned each year. However, this rises to 15-20 percent for online purchases. A microfulfillment center could also be used to help sort and process returned products which could result significant efficiency gains.

- Built in Supply Chain Resiliency

The trend of large, centrally based regional distribution centers have always made sense for distributing to stores. The labor and efficiency gains have always outpaced the risk of a natural disaster or other event which could cripple a company’s supply chain. However, by implementing a microfulfillment strategy companies now have built in resiliency to their supply chains.

Cons

- Cost

Whether you roll out one or 50 microfulfillment centers, you are going to have to spend money. Add in the cost of automation, software enhancements and labor and the cost of microfulfillment can really add up. Not including the building, a microfulfillment center will cost between two and four million dollars. There will also be internal costs associated with transferring inventory from distribution centers to fulfillment centers.

- Added Supply Chain Complexity

There is nothing simply about managing a supply chain and adding nodes will only further complicate things. Inventory distribution and balance between microfulfillment centers will be critical as a microfulfillment center is only helpful if it can fulfill orders. There are many software and automation solutions that can help manage this added complexity.

- Location Selection

Location is key. If you standup a microfulfillment center in an area that does not allow you to improve your delivery times, then you have wasted a lot of time and money. Populations also shift and a good location today, might not be as good five to 10 years from now. It’s important that a lot of time and analysis be put into ensuring your microfulfillment centers are located in the right location.

It’s important to point out that microfulfillment centers are only one tool that companies can utilize to improve delivery times. Alternative options include fulfilling online orders out of physical stores which is commonly referred to as ship-from-store, as well as negotiating with freight carriers for better discounting. Each of these have their own set of pros and cons, and neither offers the same overall impact as a standalone microfulfillment center strategy.

A recent survey showed that 40 percent of major retailers and grocers are either in the process of standing up microfulfillment centers or seriously considering doing so. One thing is for certain, end customer demand for quicker delivery times is not going to cease. Throw on top of this the millions of consumers who the COVID-19 pandemic has introduced to the world of ecommerce, and one can make a strong argument that microfulfillment centers are here to stay.