Measure: Step 2 in the DMADV Process to Improve Your Supply Chain

Marvin Logan | 05 June 2014

In this series, we've been discussing Bastian Solutions consulting’s 5-step methodology that we use in our studies. The process is a modified engineering, problem-solving approach with the acronym DMADV. The five steps are Define, Measure, Analyze, Design, and Validate. Jesseca gave the overview, but I would like to talk more about step 2 – Measure.

After we have defined the project goals, operations, and constraints, we need to measure these. How far are the goals from current state? What throughputs are required of the future operations? How big are the constraints that we need to consider? These are just some samples of the types of things we would need to measure.

We measure these in several ways. First, we need to fully understand the operations. For Bastian, that typically means spending time on the distribution or production floor. We go through all the operations/departments that could be affected by the change, asking questions, and taking notes. We may also look at current KPIs, to understand what is important and what the magnitudes of the metrics are. In some cases, we will do time studies using MOST (a pre-determined motion time system). We will also interview key personnel in support departments (e.g. IT, Purchasing, Accounting) if we think they may have an impact or may be impacted by a change.

In general, we need to be knowledgeable in the current state before we can make any recommendations. One of the most important things that comes out of the measurement phase is our request for data. Typically, we ask for one year of operating data from our client’s business systems (WMS, ERP, etc.). It may be order data, picking data, shipping container data, inventory, etc., depending on the study. Since our recommendations are data driven, this is a crucial part of the process.

For some clients, this may be an easy request; for others, it can be a challenge, and we have to work with them to fill in gaps or determine acceptable information alternatives. This request propels us into our next phase, which is Analyze.

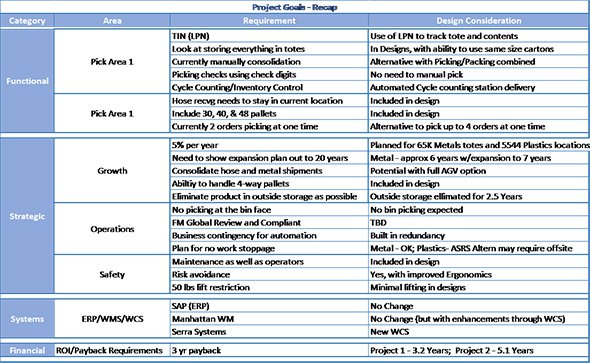

Another thing we calculate during the measurement step is the importance of the goals that came out of step 1, "define". As these goals are developed, they may have conflicting outcomes. For example, a goal of a 3-year payback on your investment may conflict or interfere with a goal of increasing capacity by 25%. So we need to understand (i.e. measure) which goal is more important than the other. Then during the recommendation stage of the design process, which is step 4, we create a grid to compare any possible solution to its impact on each of the stated goals from step 1.

The measurement step of our DMADV methodology is where we truly begin to understand the current state and needs of the client’s business. This ensures our next steps leading to a recommendation are valid.

Learn more about the next step: Analyze: Step 3 in the DMADV Process to Improve Your Supply Chain

Marvin Logan is the Vice President of Consulting and Integration at Bastian Solutions. After graduating from Purdue University, Marvin started his career as an industrial engineer and quickly moved into management. He has had roles as a distribution system manager, operations manager, director of engineering, director of distribution, and vice president of distribution for several leading companies.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.