MAYDAY MAYDAY! The Art of a Well-Balanced HMI Alarm System

Jason Beisel | 27 June 2013

After purchasing an automated material handling system, the most beneficial tool in your arsenal for monitoring that system is the human machine interface (HMI). Without an HMI, you will be flying blind when it comes to efficiently monitoring the health of your system. It is especially important that you have a superior HMI if you have a conveyor system, which can sometimes include miles of conveyors. Without an HMI, you must rely on multiple people walking the system to know how everything is flowing. That, of course, is not practical. To avoid that scenario, most of our customers rely on an HMI to do the same thing.

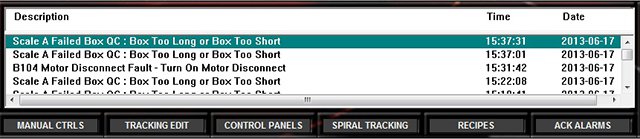

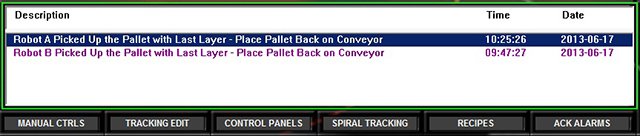

HMI Alarm System

The HMI is critical for many reasons, but the most important part is without a doubt the alarm window. However, balancing the number of alarms in your material handling system is critical to a successful HMI.

The More the Better

The argument for more alarms has some positives. By having more alarms, you can fix more issues; therefore, you will have less downtime. The problem comes when you have too many alarms, which is also known as “alarm flood”. When you have too many alarms it becomes white noise to your employees, causing it to take longer for problems to get solved.

Less is More

On the flip side of it, many people feel fewer alarms are better because employees will jump more quickly in solving issues. The white noise is no longer there, and employees can get right to the problem. The downside of fewer alarms is you might not have enough of them, so it will take longer to find the problems within your system.

Balanced Alarm Systems

The argument of more versus less alarms leads to the art of a well-balanced HMI alarm system. The best approach to getting this accomplished is first having the material handling system up and running for a few months so it has seen volume of product go through it. Next do an audit of the alarms. A controls engineer can come up with better alarms or fix the issue automatically without ever alarming it on the HMI. Some of the alarms that are duplicated or don’t provide good feedback can be taken out of alarming. You can also limit the false alarms that come up by increasing the time it takes to alarm. Monitor the changes, and overtime you’ll want to repeat this process of doing an alarm audit until the frequency works best for your operation.

Take the time to diagnose your material handling system and make modifications to your HMI alarm system accordingly. Doing so will help bring immediate improvements to your overall organization.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.