If Julia Child Upped Her Throughput: Food Grade Conveyor 101

Ahmed Arif | 16 February 2017

As standards of food manufacturing and distribution change with new mandates by the U.S. Department of Agriculture (USDA), Food and Drug Administration (FDA), Baking Industry Safety Standards Committee (BISSC), and the National Sanitation Foundation (NSF), food manufacturers and processors sometimes struggle to keep up. The regulations may require facilities to modify or even replace their existing material handling equipment for new, updated equipment that meets current standards.

Conveyor systems come in a variety of different shapes, sizes, and materials that make it possible to meet or exceed standards required by the organizations mentioned above while still optimizing your facility’s operations. This article will hopefully shed some light on which conveyor is best for conveying various food products such as bread (baked goods), raw and cooked meat, poultry and fish, RTEs (ready-to-eat items), and produce.

Sourcing Food Grade Conveyor

First, let’s start by going over the factors you want to consider when sourcing the right conveyor that will safely and sanitarily move your food product to its final destination before shipping out to consumers.

- Construction: In food grade environments, you want your conveyor system to have sanitary surfaces such as stainless steel. You also want to limit the number of horizontal surfaces that need to be cleaned. These surfaces can be collection points for contaminants, including bacteria. Along those same lines, seamless welds protect from contaminant build up. Welding beads that aren’t ground flush with the surface will create crevices that are breeding grounds for bacteria.

- Belting: Since the belt on a conveyor is the primary food contact surface, you must choose the right one for the application. Moving food requires a different kind of belting material than your typical consumer goods. You’ll need to consider the belt’s release characteristics, ability to be cleaned, heat or cold tolerance, wear resistance, and a myriad of other factors. *Different weaves may be optimal for different sizes or types of baked goods.

- Ease of Sanitation: Sanitation is the most important part of a food grade conveyor. The main thing to look for here is ease of cleaning. Conveyors need to withstand the day-to-day operation as well as the high water pressure that is used to clean the conveyor, which can be up to 1500 psi. Having a washdown-rated gearbox, motor, and chain lifter make cleaning food conveyors easier. Their tough seals will allow you to wash the equipment without removing all of the peripheral parts, which can save significant time in cleaning operations. Washdown rated equipment is typically used in tandem with CIP (cleaned-in-place) and COP (cleaned-out-of-place) processing machinery, but it can be used anywhere there’s a need for faster cleaning.

- Downtime: Manufacturing and distribution are always fighting against unnecessary downtime. Minimizing downtime by selecting a conveyor option that requires no tools to lift or remove the belt is helpful. Conveyors in the food grade environment are more modular than ever. Try looking for a conveyor option that can be dismantled and cleaned in a matter of minutes rather than hours.

Food Grade Conveyor Types

There are a large number of options out there that can solve your material handling needs in most environments. Food grade environments are the most crucial in keeping the consumers of the final product safe and unharmed from contamination due to the incorrect conveyor choice. Below are many different types of conveyors that fit many food grade conveying solutions.

Dorner’s 7600 Aquapruf Series Conveyor

Dorner’s 7600 series sanitary conveyor is an incredibly versitle addition to the food industry. It is often used in Z-Frame applications and can have a cleated belt surface to move grains and produce up an incline to be dropped into a hopper for processing or storage.

Dorner’s 7600 series sanitary conveyor is an incredibly versitle addition to the food industry. It is often used in Z-Frame applications and can have a cleated belt surface to move grains and produce up an incline to be dropped into a hopper for processing or storage.

This conveyor can also handle raw meat, poultry, and fish as well as RTE foods. Both the straight and Z-Frame options feature a complete stainless steel body with stanless steel motors for easy surface cleaning. They also come with an open style frame allowing for constant access to the inside of the conveyor when pressure washing is required. A great feature of the 7600 series is the optional belt lifters that allow easier cleaning.

This series also has no horizontal surfaces to clean as it has removable UHMW wear strips that can be taken out of the frame in a matter of seconds, making cleaning effortless. All dismantling of this conveyor is accomplished without using a single tool to minimize downtime. Each section of conveyor is said to be dismantled in approximately 2 minutes.

- Load: 20 lbs/square foot of belt

- Belt Widths: 6" to 60"

- Lengths: 36" to 40'

- Belt speed: 328 ft/min maximum

- 5" diameter drive roller with cast-on Urethane lagging

- UHMW wear strip bed plate

- Continuous TIG welded 304 stainless steel frame

- #4 Polish on all outside surfaces

- Bearing material is 400 stainless steel

- Bearing lubricant is H1 type FDA lubricant

- FDA approved belting and plastic components

Dorner’s 7400 Ultimate Sanitary Conveyor (Modular Belt and Stainless Steel Belt)

Dorner’s 7400 Ultimate series shares the same great features of sanitation as the 7600 series. It makes conveying bread, raw meat, and cooked food easy. The metal chain option is great for conveying cooked meats either to storage or even through the cooking process. The chain allows for drippings to fall below into a stainless steel catch pan making clean up simple.

Dorner’s 7400 Ultimate series shares the same great features of sanitation as the 7600 series. It makes conveying bread, raw meat, and cooked food easy. The metal chain option is great for conveying cooked meats either to storage or even through the cooking process. The chain allows for drippings to fall below into a stainless steel catch pan making clean up simple.

The 7400 series also features plastic modular belting that can convey raw meat, poultry, and fish. This belt option also allows for drippings to fall through. Plastic and stainless chain conveyors can convey baked goods such as pastries and breads through the baking process or icing applications. For icing, the chains are beneficial because the excess can be caught and repurposed for the next batch of goods that go through the line. Some additional key features include:

- Load: 20 lbs/square foot of belt

- Belt Widths: 6" to 36"

- Lengths: 36" to 999"

- Belt Speed: 233 ft/min maximum

- UHMW wear strip bed plate

- Continuous TIG welded 304 stainless steel frame

- #4 Polish on all frame surfaces

- Bearing material is 400 stainless steel

- Bearing lubricant is H1 type FDA lubricant

- USDA approved belting and plastic components

- Meets USDA, NSF and AMI design specifications

Omni Metalcraft’s Ultimate Class Sanitary Belt Conveyor

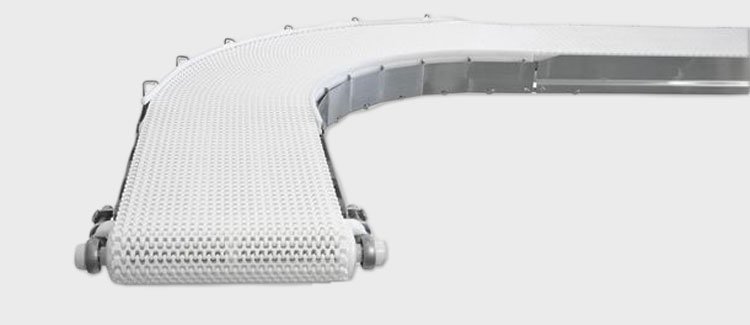

Omni can implement standard and customized solutions in the food industry. The picture above shows one of their offerings that supports direct contact surfaces to meet FDA and USDA guidelines.

Omni can implement standard and customized solutions in the food industry. The picture above shows one of their offerings that supports direct contact surfaces to meet FDA and USDA guidelines.

- Belting: Intralox modular plastic

- Frame: 10 gauge, formed

- Legs: 11 gauge square tubing with adjustable levelers

- Material: 304 stainless steel with polished finish

- Continuous TIG welding

- Washdown duty Boston drive

- Stainless steel bearings with food grade lubricant

- Solid, removable UHMW rails

Dynamic Conveyor DynaClean Food Conveyors

Dynamic Conveyor offers custom solutions to food grade applications. Similar to Dorner, the plastic pieces are assembled and disassembled without tools, making cleaning faster and easier. The custom ability allows for fitting equipment into unique spaces or integrating with specialty equipment. The DynaClean components can also be used in conjunction with other conveyor systems to capitalize on the cost savings from using standard conveyors for simple path segments within an overall system. DynaClean Features:

Dynamic Conveyor offers custom solutions to food grade applications. Similar to Dorner, the plastic pieces are assembled and disassembled without tools, making cleaning faster and easier. The custom ability allows for fitting equipment into unique spaces or integrating with specialty equipment. The DynaClean components can also be used in conjunction with other conveyor systems to capitalize on the cost savings from using standard conveyors for simple path segments within an overall system. DynaClean Features:

- Patented quick-release design gives access to all internal components

- Washdown motor and control are removed without the use of tools

- The belt can be removed with one lacing rod

- The feed roller is easily removed by lifting up and away

- Designed for clean-in-place or off-site cleaning

- Designed and built to meet NSF, FDA, USDA and BISSC standards

- Belt options include metal belting, solid surface belting and several choices of plastic link style conveyor belting

- Motors are hygienic, energy efficient and maintenance-free

- Conveyor components can be re-used to create a new washdown conveyor when processing needs change

To sum up, there are many food grade conveyor options and navigating among them can be difficult. With so many choices, it can be overwhelming to pin down the perfect fit for an application. Hopefully the information we provided can help make that choice a little easier. Please contact us to discuss your food conveyor needs.

As the Senior Director of Regional Office Solutions for Bastian Solutions, Ahmed and his teams are responsible for helping our customers achieve their goals in manufacturing, distribution, warehouse management and logistics. A graduate of Purdue University, Ahmed has been with Bastian Solutions for more than sixteen years in a variety of roles.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.