How to Reduce Total Cost of Ownership

Jaco Hooijer | 07 June 2012

This post is written by Jaco Hooijer, Operations Manager at Nedpack, headquartered in The Netherlands.

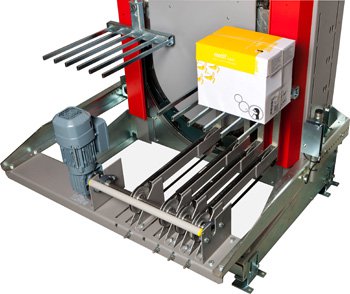

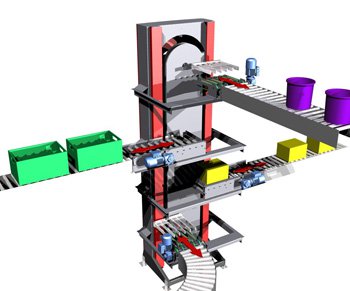

Who knows what a paternoster lift is? Anyone…? It is a passenger elevator, consisting of a chain of open compartments that moves slowly in a loop up and down inside a building. It runs continuously without stopping, and people can hop on or off at any floor they like. Paternosters were popular throughout the first half of the 20th century but fell out of favor afterward. The most important reason is they were rather slow because people needed enough time to step on or off. In the 21st century, we use this very same principle in our vertical conveyor.

This conveyor is a chain-driven lift that operates continuously in a vertical loop. A forked lift platform allows the product to be ‘scooped’ up from the loading position and deposited on the unloading position. Just like the paternoster that was used for passengers a century ago, we can attach many platforms to the chain. That’s why we can lift many products at the same time, whereas a traditional product elevator can lift just one product at a time.

Total cost of ownership

In these days, you need more than just a good idea to be in front of the material handling industry. You also have to think about total cost of ownership because that’s one of the most important aspects for most customers. The following types of costs are important to calculating a total cost of ownership:

- Purchasing costs

- Implementation costs

- Energy costs

- Service and maintenance costs

At Nedpack, we have succeeded in lowering these costs as much as possible during many years of continuous product development. A side effect is that our machine is very sustainable. How did we do that? Here are the six steps we took, and hopefully they’ll help you design more affordable products or help you purchase the right technology.

1. Less parts

When you first start building a machine, you don’t think of the number or the price of the parts you are using. You just want to make the machine do what it is meant for, regardless of what it takes. When the machine has been finished and is working the way you want, it is time to look once again at every little detail. For instance, can we make this machine as simple as possible? Do we really need every part that is used, or can we do without it? In many cases, it turned out there were better ways to get the same results, and obviously, you don’t have to pay for parts you don’t use. Buyer’s Point: When comparing technologies, it can be beneficial to find the one that uses fewer parts and still gets the job done effectively. As long as the technology meets all of your needs, you will save money over time.

When you first start building a machine, you don’t think of the number or the price of the parts you are using. You just want to make the machine do what it is meant for, regardless of what it takes. When the machine has been finished and is working the way you want, it is time to look once again at every little detail. For instance, can we make this machine as simple as possible? Do we really need every part that is used, or can we do without it? In many cases, it turned out there were better ways to get the same results, and obviously, you don’t have to pay for parts you don’t use. Buyer’s Point: When comparing technologies, it can be beneficial to find the one that uses fewer parts and still gets the job done effectively. As long as the technology meets all of your needs, you will save money over time.

2. Standardization of parts

At first, we used many different nuts and bolts in our machine. When we took a closer look at this, it turned out we didn’t need all these different fasteners. A couple of different sizes were enough. The same goes for gears, motors, and other parts. Using fewer types of parts means we can buy them in greater amounts. Thus, the price of these parts goes down and our inventory is reduced. Lastly but certainly not least, fewer types of parts makes it a lot easier for service engineers. Buyer’s Point: Not only does part standardization make manufacturing the equipment more cost effective, but it also makes the maintenance of the equipment cheaper. You won’t have to keep as many replacement parts on hand, and the parts you do have can be used for various fixes.

3. Commonly available parts

It needs no explanation that custom-made parts are expensive. That is why we use parts that are commonly available. Of course these parts are cheaper, but it is also easier to get them when they have to be replaced. A service engineer doesn’t need to call our office in The Netherlands when a machine is broken down, but can easily buy these parts at a local distributor of technical equipment. Buyer’s Point: This might be common sense, but avoid equipment with parts that you can’t easily find or will cost you large amounts of money to replace.

4. Modular design

A machine like our vertical conveyor is always a part of a bigger system like a packaging line or an automated order picking system. That means we sometimes have to adapt the machine in order to fit it in the bigger system, but the last thing we want to do is change the design of the entire machine every time. This is why our machine has a modular design. If we do have to change a part of the machine, we simply replace the old module with the new module and nothing else needs changing.

Buyer’s Point: Try not to purchase equipment that you can’t adapt to your overall system, and don’t design your entire system around one piece of technology. If you ever want to update or improve your overall material handling system, you’ll have to replace the equipment that is not modular and capable of being updated itself.

5. Dust and moisture proof

One of the things that make our machine special is that the chain gear is fixed on just one side of the conveyor, making it possible to build a solid case around it. This case prevents the products on the conveyor from getting dirty from the grease that is in the chain gear. When a chain snaps, the products won’t be damaged, and more importantly, it also prevents the chain gear from coming into contact with dust and moisture that could lead to failure.

One of the things that make our machine special is that the chain gear is fixed on just one side of the conveyor, making it possible to build a solid case around it. This case prevents the products on the conveyor from getting dirty from the grease that is in the chain gear. When a chain snaps, the products won’t be damaged, and more importantly, it also prevents the chain gear from coming into contact with dust and moisture that could lead to failure.

Buyer’s Point: Look for equipment that is well-built and capable of lasting inside facilities that contain dirt, dust, moisture, and grime. If there are a lot of exposed parts, there’s a good chance you’ll be making many repairs due to wear and tear.

6. Less energy

Using the principle of the paternoster lift, the same number of carriers goes up as goes down. In other words, these carriers balance each other. We don’t need energy for lifting these carriers, just for lifting the products. That makes our vertical conveyor very energy efficient and sustainable.

Buyer’s Point: With an influx of green products entering the market, there really isn’t a reason to not purchase more energy efficient equipment. It saves you money, decreasing your payback period on the equipment as well.

Comments

SPS Chauhan says:

8/28/2018 10:08 AM

Great Product. Looking forward to selling in India

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.