How High Can I Build My Pallet Flow Rack?

Bastian Solutions | 28 December 2015

This post, written by Judy Swajger, first appeared on Mallard Manufacturing's blog.

While there is no one-size-fits-all answer for how high pallet flow rack can go, let’s look at the major variables that are taken into consideration when designing a racking system for pallet flow.

Major Variables in Determining Pallet Flow Rack Height:

- Building Parameters

- Load & System Variables

- Pallet Load Weight

1. Building Parameters – To determine the optimal height, and therefore levels of the system, we start with the building itself. The ceiling height, building specs (including obstructions such as light fixtures, sprinkler system, ventilation), and fire code regulations are all considered in the design engineering.

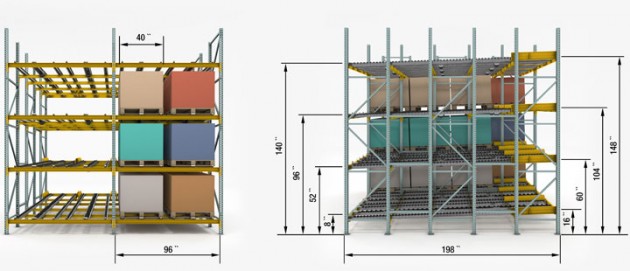

2. Load & System Variables – The next step is to look at the load and system variables. Using your largest load, identify the depth, width and height. To further define the height, now add 6” to include your pallet and another 6” for “lift-off”, the amount of space needed for forklift outriggers to insert and extract a pallet. This will give you the level height: beam height 6” (pallet) load height 6” (lift-off) = height per level

Now comes the challenge that makes pallet flow more unique vs. standard pallet rack; we still have to determine the pitch. The pitch will define the rear beam elevation. There’s no rule of thumb regarding pitch as many variables come together to define the final recommendation.

3. Load Weight – There’s one more critical variable that has impact on pallet flow rack system specs, and that’s pallet load weight. It has direct bearing on track selection, pitch, controllers and overall system capacity. The typical beam can hold about 3,000 lbs. per pallet, and most often, beams are two pallets wide allowing for about 6,000 lbs. per level.

It may seem counterintuitive, but because the beams act as upright supports, the tighter the beam spacing, the denser the design and stronger the rack bay. So a 6-level high rack structure with 5 beams is going to be stronger though it is supporting more overall weight, than a 5-level high rack with 4 beams even if they are the same height.  Once we have determined our load height, load weight, pitch and how the system will be designed to fit into the building space, we can start stacking! Add each level on to the next to determine maximum allowable system height.

Once we have determined our load height, load weight, pitch and how the system will be designed to fit into the building space, we can start stacking! Add each level on to the next to determine maximum allowable system height.

Hopefully this provides insight as to how pallet flow rack height is determined. Let us know your specs, and we’ll help you design your next gravity flow storage project.

Bastian Solutions, a Toyota Advanced Logistics company.

We are a trusted supply chain integration partner committed to providing our clients a competitive advantage by designing and delivering world-class distribution and production solutions.

Our people are the foundation of this commitment. Our collaborative culture promotes integrity, inclusion, and innovation providing opportunities to learn, grow, and make an impact. Since 1952, Bastian Solutions has grown from a small Midwest company into a global corporation with over 20 U.S. offices as well as international offices in Brazil, Canada, India, and Mexico.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.