Fixing a Conveyor Belt Tracking Issue

Wes Bryant | 19 September 2018

A Customer Service Story

At Bastian Solutions, we pride ourselves in providing exceptional service and flexibility to our customers – even if it means fixing an issue on equipment we didn’t sell or install.

I have a customer that buys replacement parts from time to time, but never conveyor or other material handling equipment. They originally purchased everything from an out-of-state integrator, which was the only reason I was able to get in for parts and service.

The customer had recently purchased two slider bed conveyors from the other integrator, handling the installation and set-up themselves. My first thought was with a new conveyor, the only part they’d possibly need was a spare belt. I offered a quote and included some additional guarding to keep operators away from the drive and tail pulleys.

Belt Tracking & Troubleshooting

After a month or so of running, the customer called and asked if I could come in to look at the belt tracking, as both conveyors were having issues. Sure enough, the belts would track from side to side, running off the edge of the drive pulley and fraying the sides of the belt. So, I went through my normal troubleshooting process:

- Is the conveyor level and square in all directions?

- Is the belt tensioned properly?

- Is the take up and tail pulley properly lined up?

- Are the snub rollers aligned correctly?

- Is the drive pulley square with the conveyor bed?

Although the conveyor was not perfectly level, everything else passed inspection. I knew it was a long shot, but I re-leveled the conveyor and watched it run. Sure enough, the belt would still randomly wander from side to side. So, I went through everything again and found the same results. Of course by now the customer was running out of patience. They were asking about replacing the conveyor or having the manufacturer try to service it.

I knew I had done everything correctly, but I reached out to the manufacturer for guidance. They asked me to go through the belt tracking process again, and believed it was likely installed incorrectly. However, since both conveyors were doing the same thing, I believed it was a component problem. The manufacturer went through the bill of materials and the engineering drawings and confirmed everything was correct per their design.

Resolving the Issue

By this time, I had made multiple site visits over two weeks for a conveyor that my company had not sold, but I was determined to fix the problem and take care of the customer. Convinced it was a component problem, I kept talking to different engineers at the manufacturer. I had an idea that the drive roller was incorrect and felt it should be crowned instead of flat, even though all the cut sheets and drawings called for a flat roller. I finally talked to an engineer who confirmed that they sometimes had this same problem, and in fact, a crowned drive roller was the only solution for these instances.

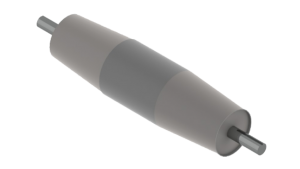

A crowned roller is thickest in the middle, which creates a channel that helps to keep the belt centered or track back to center if pushed by lateral forces. The manufacturer sent the customer two new crowned rollers, which I installed with immediate good results.

By staying persistent and taking care of the customer, I was able to solve the problem and gain their trust and business.

The moral of the story is that not every application is the same, and sometimes the typical design is not the right solution. That’s why it’s important to have an experienced, dedicated integrator that will take the time to find the best equipment for your needs and fix any unexpected issues that may arise.

Comments

Essar Airsystems says:

2/28/2019 12:19 AM

thank you for providing such an informative article

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.