Ergonomic Benefits of Industrial Robotics

Matt Kohler | 05 November 2015

To protect employees and eliminate risky operations, companies are turning to industrial robots to assist in grueling work conditions.

Pretend it’s your first day on the job. You just got finished saying goodbye to your wife and two children, made the commute to work, and are looking forward to your new job as a plant operator at a large manufacturing facility. At this point in your career, you are looking to do whatever your manager wants you to do to help with the operations of the plant. The word “no” is not in your vocabulary for the next few weeks! Well, what would be your initial reaction when your manager tasks you with one of these grueling jobs?

- Palletizing 50-100 lb sharp, scrap aluminum bales

- Repetitively placing a widget from a conveyor belt to a fixture, every single second for your entire 8-hour shift

- Manually stacking heavy, lead-acid batteries

- Bending over and picking up cases of beverages from the floor to the top layer of a pallet all day

- Reaching in and out of a sharp, milling machine throughout the shift while making sure to keep your arms and fingers out of harm’s way

I imagine your first reaction would be somewhat hesitant as you begin to think of some of the risks of each of these tasks. It would be hard not to think about the importance of making it home safe that night to see your family and continuing to work diligently for the company that gave you this opportunity. Hundreds of thousands of people have to deal with risky work environments, dodging workplace injuries, and making it home to their families every day. There are industry shifts, however, that are seeking to reduce the need for utilizing human labor in these inherently risky operations and shifting them to safer tasks in the facility.

Current State of Workplace Injuries

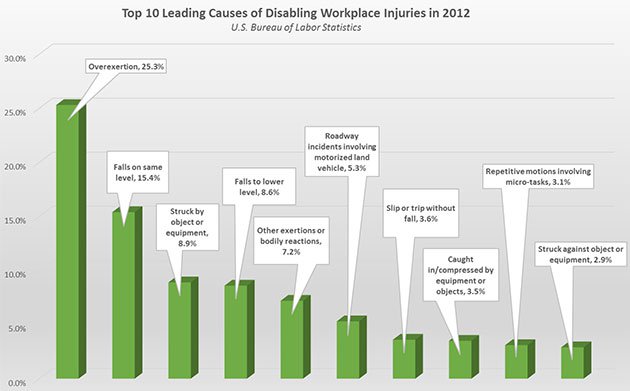

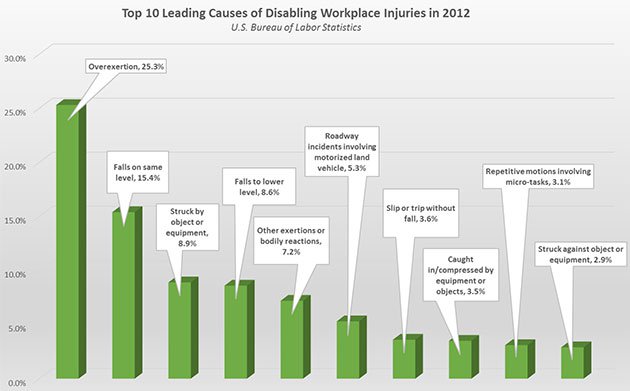

According to the U.S. Bureau of Labor Statistics, the 10 leading causes and direct costs of the most disabling workplace injuries in 2012 were:  It is clear that all of these root causes of workplace injuries could be minimized by many different strategies. Many organizations have strict safety protocols for all operators to follow. Educating workers on the proper way to go about their daily tasks is of paramount importance to improving these statistics. On the other side, some companies struggle with documenting these strategies and fail to make safety a priority in their operations. Alternatively, many companies are taking the stance that some of these jobs are just not meant to be left to a human who is looking to make it home healthy at the end of the day. These progressive organizations are looking to automate the risky, dirty, and unsafe tasks in their facilities.

It is clear that all of these root causes of workplace injuries could be minimized by many different strategies. Many organizations have strict safety protocols for all operators to follow. Educating workers on the proper way to go about their daily tasks is of paramount importance to improving these statistics. On the other side, some companies struggle with documenting these strategies and fail to make safety a priority in their operations. Alternatively, many companies are taking the stance that some of these jobs are just not meant to be left to a human who is looking to make it home healthy at the end of the day. These progressive organizations are looking to automate the risky, dirty, and unsafe tasks in their facilities.

How Robotics Can Help Improve Industry Ergonomic Issues

When you look back at the Top 10 Leading Causes of Workplace Injuries, one could argue that all but maybe one or two could be improved by implementing robotics. Of course, there are many tasks that are simply not feasible for a robot to undertake. Robotic integrators, such as Bastian Robotics, can help make that determination and provide creative solutions to help companies meet their strategic and safety objectives. Look back at the initial scenario that was posed at the beginning of this article regarding the different positions a new employee at a manufacturing facility could be put in. Bastian Robotics has implemented robotic systems to improve the operational ergonomics for all of those listed scenarios:

Justifying Robotic Projects

Labor safety and the costs associated with workplace injuries are becoming an increasingly prevalent factor in justifying the implementation of robotic projects. Looking at a project on strictly a labor-cost, simple payback criteria could leave out a large portion of costs associated with the ergonomic conditions of a particular operation. Many companies have already performed an analysis to apply a particular $/hour rate to be added to the burdened labor rate used in the economic evaluation of a project. Other organizations simply consider this an intangible benefit to a system and consequently allow for some flexibility in their conventional payback criteria due to this inherent improvement.

The way organizations first identify the ergonomic and safety risks within their operations, determine a route forward, and justify the route forward are all different. Reducing insurance rates, workers compensation payouts, and increasing system uptime are some of the economic objectives of improving these conditions. The most important, however, is sending that worker back to his or her family at the end of the day.

Bastian Solutions values the responsibility to provide systems that help clients accomplish these objectives. Contact us to help improve your ergonomic conditions.

Matt Kohler, Bastian Solutions Director of Applications has been with Bastian Solutions since 2005, after receiving his degree in mechanical engineering from the University of Missouri - Columbia. The applications team at Bastian Solutions prides themselves on thoroughly understanding their customer’s unique needs and then tailors a solution that gives those customers a competitive edge in their business.

Comments

lopez vasquez says:

8/28/2018 10:09 AM

I have been following you and I have observed how you improve the methods of work, is interesting how practical your robots are and not only that, is really wide the fields you encompass.

I have a question for you How do you motivates your employees so that they have that kind of inventiveness? Sometimes is in the edge of the amazing the projects that you have presented. I congratulate you and hope to see more inventions. Thanks

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.