Enclosed Track Overhead Conveyor: True, Tried and Tested

Ben Viorel | 09 May 2013

Enclosed track overhead conveyors have been around for many years, some dating back to 1919 when they were used in automotive assembly plants. Simply described, enclosed track overhead conveyor is a series of trolleys with a load, suspended by an overhead track and connected to a continuous running chain, which can run winding both horizontally and vertically.

Most people have seen them commonly used in a dry cleaning shop retrieving their dry cleaned clothing. However, this type of conveyor is not just for moving automotive parts or clean clothes. It provides a host of benefits, which I’ll talk about in a minute. But first, let’s look at the main components of this conveyor: the chain and the track. After which, I’ll review the key advantages and common issues that can occur with this type of conveyor.

The Chain

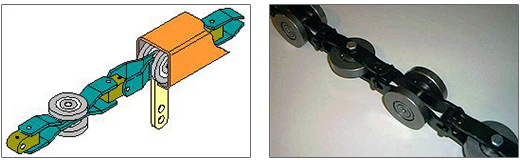

The chain on an enclosed track overhead conveyor is made of formed C-1045 high carbon steel side bars connected in paired series with a drop forged 1045 high carbon steel pin. The 4-way pins allow for the chain to flex in both directions. Load wheels are assembled every 3rd pitch with side guide wheels on each alternate pitch.

The Track

The track is made of formed square tubular 1030 high carbon manganese steel complete with a jig welded yoke at each end, allowing for correct alignment when bolting the track together at installation.

Advantages of Enclosed Track Overhead Conveyor

Listed below are some of the main reasons this type of conveyor should be used as an economic solution to automate processes within a facility.

- Frees up floor space

- Takes goods to an operator

- Can change directions both in the vertical plain and horizontal plain

- Multiple drives allow for extended lengths

- No welding required for installation of the track

Things to Watch

Although there are many advantages to this type of conveyor, there can be operational issues if it is not properly installed or maintained. Luckily, each of these items can be answered by working with qualified engineers on an acceptable resolution for successful design and implementation.

- Correct placement of drive and chain pull calculation

- Ample take-up and placement of take-up assembly

- Lubrication, either automatic or manual brush

- Possible contamination of track from ambient conditions

From its beginning in 1919 to its automation capabilities today, enclosed track overhead conveyor has established itself as a true, tried and tested form of material handling equipment. If you haven’t considered using it to establish an economical form of automation in your facility, it is worth a look.

Comments

gerry thompson says:

8/28/2018 10:08 AM

iam looking for about 2meters of enclosed track with a wheel assembley to suit for the elevated perposed under a timber deck can you help

Clarissa says:

8/28/2018 10:08 AM

Christian says:

1/29/2020 01:03 PM

Hello!

I'm a project manager at Tesla and I'd like to inquire on a overhead conveyance system for the S/X production line

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.