Defining the Problem: Step 1 in the 5-Step Decision Making Process to Improve Your Supply Chain

Marvin Logan | 22 May 2014

In a previous article, we started the discussion on the 5-step decision making process, DMADV, and how it helps you make better decisions in your supply chain or any area of your business. In a series of articles, we’ll further explore and define each step so you can get the most out of this process.

The First Step is the Hardest

DEFINE: The first step in making a decision or solving a problem is to define it. This first step is one of the most critical ones. You have to accurately and adequately define the constraints, the current operations, and the goals. If you spend the time upfront defining the requirements and constraints, you’ll be able to determine whether or not the solution you’re considering is the right one.

Many people want to skip the defining step and get straight into solving the problem. You’ve identified what the problem is, isn’t that enough? Albert Einstein once said that if he had an hour to save the world, he’d spend 55 minutes defining the problem and 5 minutes solving it. That implies there is more to the definition step than just saying you have a problem. But what exactly do you need to define?

Visualizing the Problem

When the consulting team is asked to help solve a problem with a customer’s supply chain or warehouse, we start with a walk-through of the facility. As we travel through the customer’s facility, we gather notes on the problems, the things that are working, and any practices or methodologies currently in place. This walk-through serves a couple purposes.

- The first reason for the walk-through is to examine the problem more closely.

- The second reason is to better understand what is contributing to the problem.

Very rarely are problems isolated to one area. There’s typically something upstream or downstream of the issue that’s contributing.

Brainstorming the Requirements and Constraints

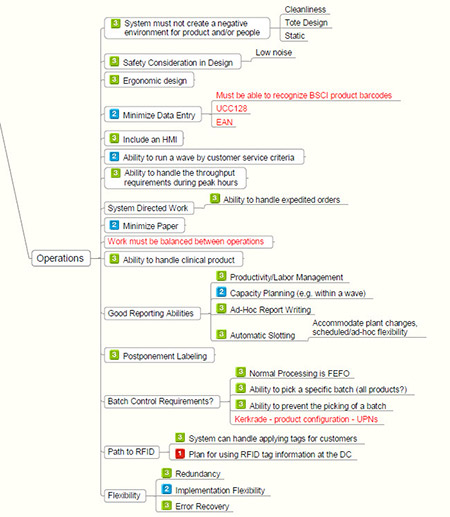

After visualizing the problem with a walk-through, the next step is to brainstorm. In order to help with the brainstorming and make sure we don’t leave anything out, we use a template. Our template includes various business requirements and examples for each requirement.

Some of those business requirements are financial, functional, operations, and strategic. In each of those areas, we have a few items to kick-start the thought process, such as listing the return on investment (ROI) under the financial area. We’re looking at quantitative and qualitative items in order to determine the evaluation criteria. If you don’t determine the evaluation criteria up front, you won’t be able to decide on the best solution to your problem.

Brainstorming business requirements and constraints, helps define a problem and create a better solution.

Next Step - Measure

Now that the requirements and evaluation criteria have been defined, the next step is to measure. Read the next article in this series: Measure: Step 2 in the DMADV Process to Improve Your Supply Chain

Marvin Logan is the Vice President of Consulting and Integration at Bastian Solutions. After graduating from Purdue University, Marvin started his career as an industrial engineer and quickly moved into management. He has had roles as a distribution system manager, operations manager, director of engineering, director of distribution, and vice president of distribution for several leading companies.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.