Automated Picking Technologies for Omni-Channel Fulfillment

Mike Clemens | 11 October 2018

What is an Omni-Channel Warehouse?

Omni-channel warehouses share a common inventory between multiple channels of distribution. Typical distribution channels may include a mix of:

- Retail orders – tend to be either large push distributions to stores with high SKU’s and units or smaller “replenishment” orders with only a few SKU’s and units.

- Wholesale orders – “in-between” in size and could have different seasonal peaks.

- E-commerce orders – usually smaller, with low SKU and unit counts and have a traditionally large volume spike in November.

To run effectively, complex operations like omni-channel require the right mix of planning, software, and equipment. In this article, we’re going to focus on equipment – specifically, automated technology.

Key Technologies to Consider

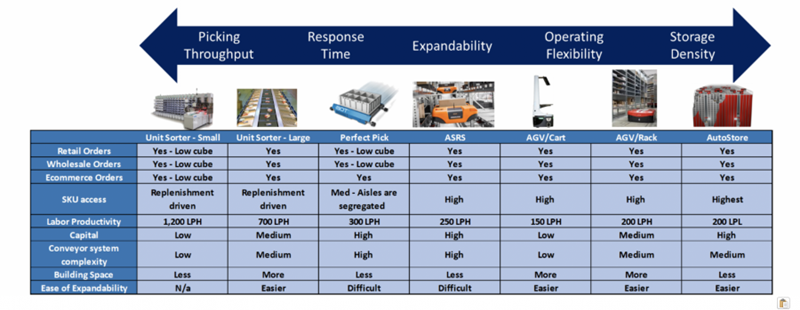

There are various automation technologies available to effectively support the fulfillment of multiple order types from a single facility. Multiple factors must be considered to select the best option.

One key consideration in selecting the right automated solution is the overall picking strategy; should you pick to discrete orders or pick in larger “batches” of multiple orders? At lower volume levels, discrete order picking may be the most efficient, but at higher volumes batching techniques may be better to minimize the overall cost of an automated solution. Order profiles, operating hours, volumes, available space and labor costs must also be considered.

Below are descriptions of some best-practice equipment systems that are available.

Small Unit Sorters (i.e. Sure Sort) can be described as an “automated put-wall”. They have been around for some time and tend to have niche applications. However, a recent innovation has been the use of high-speed shuttles to perform the sorting task. This allows a single induction operator to feed a system that sorts up to 1,200 lines per hour into 400 unique destinations. Its benefits can be a larger order batch size for picking and a huge increase in put-wall labor productivity. It works best for low cube items in a multi-shift environment. It can be a stand-alone solution or can be coupled with other technologies when an operation picks orders in large “batches”.

Small Unit Sorters (i.e. Sure Sort) can be described as an “automated put-wall”. They have been around for some time and tend to have niche applications. However, a recent innovation has been the use of high-speed shuttles to perform the sorting task. This allows a single induction operator to feed a system that sorts up to 1,200 lines per hour into 400 unique destinations. Its benefits can be a larger order batch size for picking and a huge increase in put-wall labor productivity. It works best for low cube items in a multi-shift environment. It can be a stand-alone solution or can be coupled with other technologies when an operation picks orders in large “batches”.

Large Unit Sorters (i.e. X-Belt) can handle a wide range of volumes but are especially useful for 10,000 units per hour and above. At these higher volumes, they become very cost-effective compared to goods-to-person technologies. Operator productivity includes both input (induction) and output processing (packing), but in a well-designed system, the net productivity can be very high. These systems are adapted to a small order environment by adopting a variety of sorting and waving strategies and adding manual put-walls. The major drawbacks of these sorters are the large footprint, requiring extensive conveyor feed and removal lines, as well as the multiple handling steps that can reduce overall labor productivity.

Large Unit Sorters (i.e. X-Belt) can handle a wide range of volumes but are especially useful for 10,000 units per hour and above. At these higher volumes, they become very cost-effective compared to goods-to-person technologies. Operator productivity includes both input (induction) and output processing (packing), but in a well-designed system, the net productivity can be very high. These systems are adapted to a small order environment by adopting a variety of sorting and waving strategies and adding manual put-walls. The major drawbacks of these sorters are the large footprint, requiring extensive conveyor feed and removal lines, as well as the multiple handling steps that can reduce overall labor productivity.

Perfect Pick (dedicated aisle) is a very high-throughput goods-to-person system that is especially well suited for low cube items and small line count orders. Each picking aisle has a tall rack structure for totes or cartons (on trays) that are transported to end-of-aisle pick stations by high-speed shuttles. There can be a pick station at each end of an aisle. The shuttles are captive to an aisle, meaning that if an order requires picks from multiple aisles, the order container must be moved between aisles by an external conveyor system. The picker usually picks for a small batch of order containers, to maximize pick rates, which can be as high as 300 lines per hour.

Perfect Pick (dedicated aisle) is a very high-throughput goods-to-person system that is especially well suited for low cube items and small line count orders. Each picking aisle has a tall rack structure for totes or cartons (on trays) that are transported to end-of-aisle pick stations by high-speed shuttles. There can be a pick station at each end of an aisle. The shuttles are captive to an aisle, meaning that if an order requires picks from multiple aisles, the order container must be moved between aisles by an external conveyor system. The picker usually picks for a small batch of order containers, to maximize pick rates, which can be as high as 300 lines per hour.

ASRS Shuttles (aisle-changing) are another type of goods-to-person system that usually has a separation (decoupled) between the carton /tote storage area and the picking stations. This separation allows product from any aisle to go to any picker but requires the incorporation of an extensive conveyor system. The ASRS shuttles operate in tall rack aisles that have an end-of-aisle lift to raise and lower containers between storage levels. The lift becomes the limiting factor in throughput for an aisle. Today, 250 dual cycles-per-hour rates per aisle can be achieved. Recent innovations have added the option for a second lift to nearly double the throughput potential of an aisle. Rack storage can be single or double deep and can be customized for a wide range of load sizes.

ASRS Shuttles (aisle-changing) are another type of goods-to-person system that usually has a separation (decoupled) between the carton /tote storage area and the picking stations. This separation allows product from any aisle to go to any picker but requires the incorporation of an extensive conveyor system. The ASRS shuttles operate in tall rack aisles that have an end-of-aisle lift to raise and lower containers between storage levels. The lift becomes the limiting factor in throughput for an aisle. Today, 250 dual cycles-per-hour rates per aisle can be achieved. Recent innovations have added the option for a second lift to nearly double the throughput potential of an aisle. Rack storage can be single or double deep and can be customized for a wide range of load sizes.

AGVs (built-in cart) with built-in shelving have been designed to replace the manual picking cart. While there are many strategies in using these vehicles, the most productive minimize picking operator walking distances to improve efficiencies. Picking rates can vary significantly, but there can be a 3x improvement over manual methods with a comparative estimate of 150 lines per hour. These vehicles allow automation at a lower price point and are designed to work in an existing bin shelving environment. An AGV system of this type needs to have access to all picking locations on a single floor level.

AGVs (built-in cart) with built-in shelving have been designed to replace the manual picking cart. While there are many strategies in using these vehicles, the most productive minimize picking operator walking distances to improve efficiencies. Picking rates can vary significantly, but there can be a 3x improvement over manual methods with a comparative estimate of 150 lines per hour. These vehicles allow automation at a lower price point and are designed to work in an existing bin shelving environment. An AGV system of this type needs to have access to all picking locations on a single floor level.

AGVs (mobile racks) handling mobile racks offer tremendous flexibility in the types and sizes of product that can be handled. This approach, once pioneered by Kiva, is making a resurgence. The low-profile automated vehicles transport custom-configured shelving racks containing product inventory. Operating in an enclosed “grid” area, the vehicles deliver individual racks to picking stations. A system may have 30 plus vehicles and 300 plus racks, essentially automating a manual bin shelving forward pick area. Vehicle movements can be synchronized to deliver up to 200 racks (lines) per hour to pick stations, resulting in high productivity. A limiting factor is that the system typically operates on the warehouse floor or a structural mezzanine.

AGVs (mobile racks) handling mobile racks offer tremendous flexibility in the types and sizes of product that can be handled. This approach, once pioneered by Kiva, is making a resurgence. The low-profile automated vehicles transport custom-configured shelving racks containing product inventory. Operating in an enclosed “grid” area, the vehicles deliver individual racks to picking stations. A system may have 30 plus vehicles and 300 plus racks, essentially automating a manual bin shelving forward pick area. Vehicle movements can be synchronized to deliver up to 200 racks (lines) per hour to pick stations, resulting in high productivity. A limiting factor is that the system typically operates on the warehouse floor or a structural mezzanine.

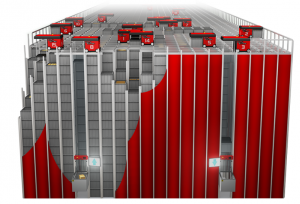

AutoStore is a unique goods-to-person storage and picking system that can deliver any bin in its inventory to any picking station that is attached to its bin storage array. The storage bins are densely stacked on the floor, resulting in over 50% space reduction when compared with other methods. This system uses small robots to traverse a grid above the bin stacks, which store, retrieve and transfer the bins to ports. Operators can then pick from or replenish the inventory. Due to the nature of accessing bins from the top of the system, bin rotation ensures the fastest-moving product remains towards the top of the system. The typical Pareto curve (20% of SKUs >= 80% of Lines) works well for all order types. Bin dimensions are fixed, which may be limiting, but pick rates of 200 lines per hour are achievable.

How can I get help in sorting through all of these options?

Bastian Solutions consultants are knowledgeable experts who can work with you and your team to explore the possibilities for omni-channel fulfillment in your warehouse. We can leverage our firm’s expertise, utilizing the best option(s) out of all the leading technologies, providing you with an efficient, cost-effective fulfillment operation.

Mike Clemens is a principal consulting engineer with the Bastian Solutions consulting group. Mike has more than 30 years of client engagement experience focused on the development, cost justification and delivery of automated material handling systems for manufacturing and warehousing applications.

automation,

AGV,

AGVs,

Automated Guide Vehicles (AGVs),

automated storage and retrieval,

goods to person,

goods to person systems,

goods to person technologies,

goods-to-man,

omni-channel distribution,

omni-channel fulfillment,

robotic AGV

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.