Another Broken Pallet! Tips for Better Pallet Handling

Geoff Schreiber | 10 July 2014

I was contacted recently by my brother, who is an engineer at a large food processing company, about an issue they were having with one of their pallet handling systems. The title of the email that was forwarded to me was “Another broken pallet”. It was as if they had been fighting this issue for an extended period of time and were finally fed up with it.

As you can see from the pictures below, they were having issues with one of their pop-up pallet transfers. After speaking with him briefly, the solution was obvious to me. They were transferring full pallets on a two chain pop-up transfer and really needed three chains in order to take some of the load off the bottom boards on the pallet.

Although handling pallets might seem simple, there are many things to take into consideration when selecting the right equipment in a pallet handling system. There are MANY different variations of pallets out there, so here are a few items that you should consider before selecting your pallet handling equipment.

- What type of pallets does your company use? Are they standard GMA’s? CHEP’s? Plastic? Steel? Aluminum? 2 way? Partial 4 way? Full 4 way?

- What is the condition of your pallets? Are they brand new every time? Are they reused? Are they repaired? Are they frequently missing boards?

- How stable are your full pallet loads? Do you have any small cases in production? Have you had issues in the past with loads falling over?

All of these variables play a huge role in determining how to dispense, stack, convey, and transfer pallets in an automated fashion. Starting at the beginning of a typical pallet handling system, here are a few general rules of thumb.

- If you use pallets that are of questionable condition, use a fork style pallet dispenser. A fork style pallet dispenser is the most forgiving type of pallet dispenser and in general, if you can pick up the pallet with a fork lift, a fork style pallet dispenser will work very well for you. If your pallets are very consistent, there are many other options to choose from.

- If the bottom boards on your pallets run parallel to the direction of travel, use chain driven live roller conveyor, otherwise, use drag chain conveyor. Chain driven live roller conveyor is typically a little less expensive than drag chain conveyor, so using that to conveyor your pallets will result in a less expensive system in most situations.

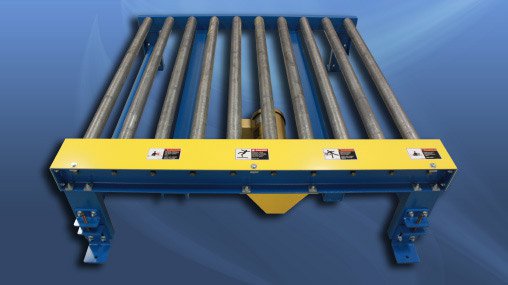

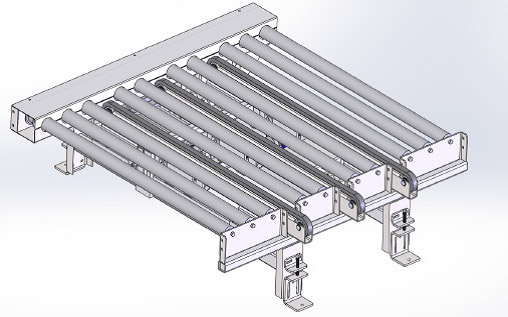

- If your full pallet loads are anything less than solid structures, use a positive, wedge style pop-up transfer when transferring your pallet loads ninety degrees (not an air bag lift). Also, if you are transferring any loads over one thousand pounds on a typical wooden pallet, a three chain pop-up transfer is recommended. Wedge style pop-up transfers are raised and lowered using cam followers pushing on steel “wedge” profiles to ensure that the entire frame is moved uniformly, which results in a very smooth vertical motion.

In conclusion, there are many different items to take into consideration when designing a pallet handling system. If you are unsure about any piece of equipment in your pallet handling system, please contact us.

Geoff Schreiber is the Engineering Manager for Bastian Solutions robotics division in Saint Louis, MO. His role includes leading the engineering efforts of the mechanical, electrical, and automation disciplines for standard and custom projects as well as coordinating the research and development of new robotic technologies such as goods-to-robot bin picking for fulfilment and replenishment operations. A graduate of Southern Illinois University Edwardsville, Geoff has over 20 years’ experience in software and PLC development in addition to technical design direction for mechanical and electrical products, parts, and components for equipment and machinery.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.