Accurately Visualize Robotic Systems with Computer Simulations

Michael Cunningham | 9 June 2021

As industrial robotic technology has improved over the years, so has related simulation software. So much so, that a majority of the upfront programming for a robotic system is typically now completed in simulation software first before being implemented in a physical robot.

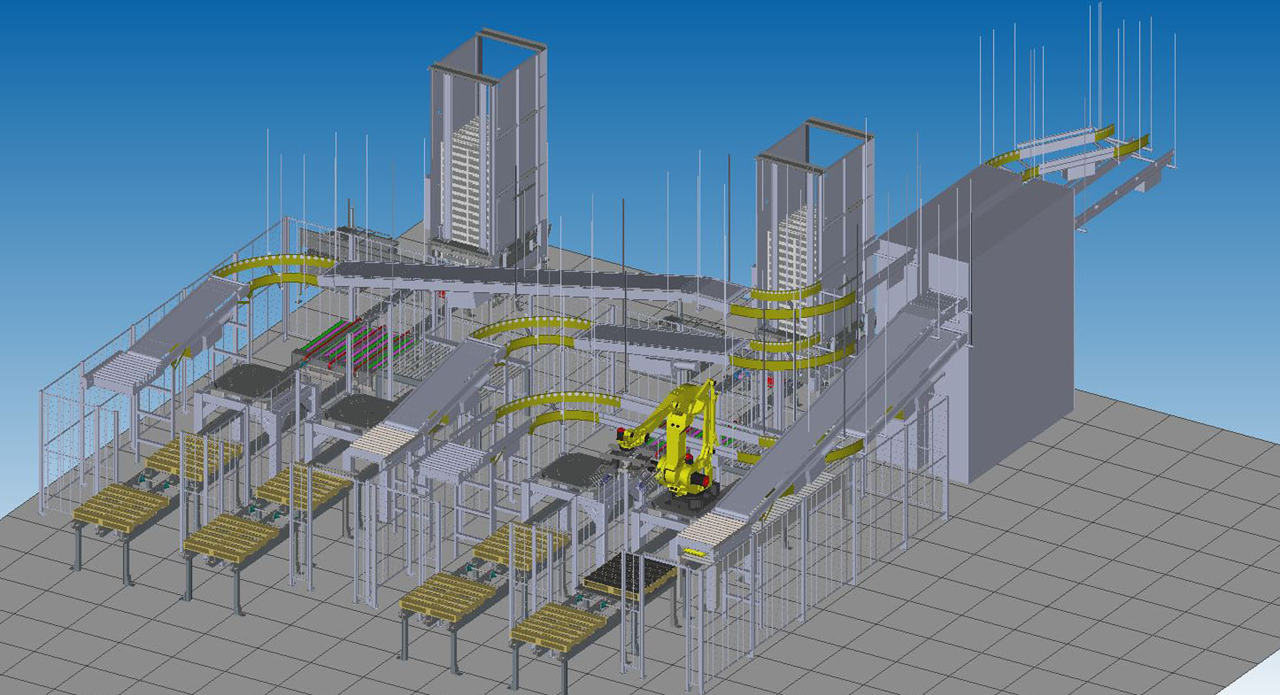

The sophisticated software programs used for robotic simulations replicate real world robotic conditions within a 3D virtual environment. These tools allow for detailed customization providing a reliably clear view of how a robot will operate before its built and integrated. This gives customers peace of mind of how their investment will support their operations.

Making the Most of Robotic Simulations

In a robotic simulation, a user sets up custom conditions by utilizing the built-in robot models that have all of the dynamic limitations of a real robot including:

- Range of Motion

- Speed

- Payload

The simulation software extends to detailed components on the robot so you can pair 3D models of end of arm tools with the robot. You can apply accurate payloads to adjust and confirm payload details as well as related robotic movements.

The simulation software extends to detailed components on the robot so you can pair 3D models of end of arm tools with the robot. You can apply accurate payloads to adjust and confirm payload details as well as related robotic movements.

Additionally, the simulation tools allow you to add 3D models of additional equipment to view how the robot will maneuver around them. This helps you have a better sense of how the robot will interact with existing or new equipment like conveyors or a CNC machine.

Once the environment has been setup, the user can begin programming the simulation utilizing the many built-in software tools or the virtual teach pendant, an identical representation of a physical teach pendant used to control the robot’s motion. This will look and function exactly like it will once physically installed on-site.

Validate and Save

Robotic simulations provide numerous benefits, with a lot of them being able to be categorized into the two main areas – proof of concept and design, and reduced integration costs.

Proof of Concept and Design

Due to the sophistication of the simulation software, manufacturers can accurately prove that the system design will work and meet expectations as planned, prior to implementation.

With a simulation, a user can:

- Identify interferences between the robot and surrounding equipment.

- Prove that the robot will be capable of meeting pick and place rates.

- Prove that the robot is capable of reaching all pick and place locations with the attached end of arm tool.

- Prove that the robot can handle the payload of the end of arm tool and the product simultaneously.

- Determine if additional items are needed to support the robotic system, such as cooling fans for the motors.

Reduced Integration Costs

The virtual nature of computer simulations includes benefits that ultimately allows for higher efficiency, contingency planning, and faster, better understanding for customer team members. Robotic simulations allow you to:

Optimize – Ensure your system is fully optimized and reduce risks associated with automation before you spend capital on any physical hardware.

Program – Program the robotic system prior to a physical setup, reducing implementation time significantly as it can sometimes take months before a system is fully setup and ready to go.

Troubleshoot remotely – Assuming the issue is not something that completely shuts down production, you can continue to get beneficial use out of the system while you work out the issue in the simulation software.

Confirm Before Robotic System Installation

Robotic order fulfillment technology has rapidly developed over the past couple years, and through the support of computer simulation tools we have access to detailed customization allowing for greater accuracy and confidence before they’re built and integrated. Bastian Solutions can help you implement the right solution to fit your industry and application needs, maximizing your return on investment.

Michael Cunningham is a robotics inside application engineer at Bastian Solutions' St. Louis, MO office. He has a Bachelor of Science degree in Mechanical Engineering from the University of Toledo. As an inside applications engineer, Michael works with clients on the requirement analysis, design, budgeting, proposal, and implementation of robotic material handling systems.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.