A Guide to Dock Boards and Dock Plates

Greg Ward | 26 July 2016

Any facility you go into that requires material handling equipment, will most likely have one, if not more, dock doors. Dock doors are the life line to get your customers product in and out of the facility. So, how do you handle the transition from the carrier (via truck) to getting the product into the building and back out? Whether you choose a dock board or dock plate to span the gap between your building and the product on the truck, choosing the one that best fits your environment is important. So, which one is right for your application and environment?

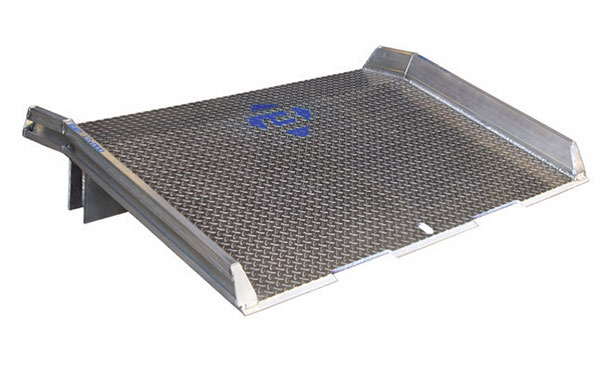

Dock Boards – Are a heavy duty piece of equipment with side curbs designed to prevent machinery (fork trucks) from rolling off the edge.  Dock Plates – Are smaller and a more portable equivalent to a dock board. A typical application is the use of a non-powered machine (pallet jack) for loading and unloading.

Dock Plates – Are smaller and a more portable equivalent to a dock board. A typical application is the use of a non-powered machine (pallet jack) for loading and unloading.

Selecting a Dock Board or Plate:

Step 1: Determine the capacity

- Equipment weight max load weight

Step 2: Determine the overall width required

- Dock boards or plates should be at least 15” wider than the load of equipment passing over it.

Step 3: Determine the plate length (based on an empty truck/trailer) If the height difference between the bed of the truck and dock floor is:

- Up to 8”, no less than a 48” length

- Up to 10”, no less than a 60” length

- Up to 12”, no less than a 72” length

Dock Safety:

One of the biggest elements of dock board and dock plate safety is transportation and handling. Because they handle heavy equipment and material, they too are heavy.

- Workers should never try to move a dock board by themselves

- Dock plates are lighter, but it is still important to follow proper lifting techniques.

- Inspect dock boards and plates to ensure they are not damaged. When moving heavy equipment or material over them, injury could be a result of defective equipment.

- Mark floors with yellow tape or paint to identify walk ways.

Other dock safety items could include:

- Dock lights

- Dock bumpers

- Trailer chocks to stabilize trailers during loading and unloading

- Lever lifts or chains for setting in place and removing.

Our team would be glad to help you evaluate which dock board or plate makes sense for your operation. Learn more about dock equipment on our website or give us a call today.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.