6 Helpful Tips when Working with CAD

Jim Sutherin | 02 May 2013

Computer-aided design programs have become a staple in many engineering firms. We use them everyday for designing

conveyor systems and various

custom technologies, so at least some common knowledge and use is needed as drawings are passed from engineer to engineer. Sometimes, however, it can feel like an uphill battle trying to get these programs to cooperate. They have a tendency to be buggy, crash, or unable to execute certain commands, but there are steps you can take to reduce the risk of things going wrong and to produce better drawings. Most of these steps apply to the majority of CAD programs, and although some people might think these tips seem too simple, I think they are things we all forget or become sloppy with as we progress.

CAD Tips 101

- Save early, save often: If Murphy’s Law applies to anything, it’s CAD programs. They have a tendency to freeze and crash, usually losing all of your work. It’s also a good idea to make multiple save files, at least one per day, so you can go back to an earlier design or idea. This also lets you track your drawing changes through the design process.

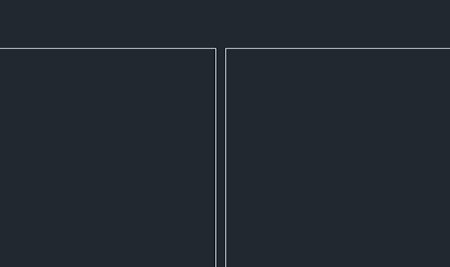

- Check for connections and overlap: You might think your drawing is clean and even, but sometimes it’s best to take a closer look. Because of the scale and limits of CAD systems, not all defects can be seen. Take the example of the two identical corners shown below. They both appear to be perfectly perpendicular, joined sides.

But if we were to zoom in much closer…

But if we were to zoom in much closer…  …there’s a small gap on the right corner which could cause problems in fills, connections, and dimensions. In fact, if you were to look much closer, you’d be able to see the lines on the right are not perfectly perpendicular either. The problem with that is the difference is so small that if you were to dimension the angle, it might round up to 90°. The impact of these mistakes depends on your scaling of course. Being slightly off with a scale of feet may only be a difference in millimeters. However, a poor drawing in miles could be noticeably inches off its intended mark. The best ways to combat these in AutoCAD are with the ortho, trim, and extend command.

…there’s a small gap on the right corner which could cause problems in fills, connections, and dimensions. In fact, if you were to look much closer, you’d be able to see the lines on the right are not perfectly perpendicular either. The problem with that is the difference is so small that if you were to dimension the angle, it might round up to 90°. The impact of these mistakes depends on your scaling of course. Being slightly off with a scale of feet may only be a difference in millimeters. However, a poor drawing in miles could be noticeably inches off its intended mark. The best ways to combat these in AutoCAD are with the ortho, trim, and extend command.

- Check what’s selected: When selecting an object in busy space, it’s very easy to select the wrong object. What’s worse is when you don’t realize the mistake, and you’ve modified the wrong features. In AutoCAD, you can control how much you highlight depending on which direction you drag the cursor. A blue box selects items completely enclosed by the space, and the green box selects everything that’s partially inside. You can also deselect items by holding down the shift key.

- Layer control: This is a big step in conquering larger drawings. Using more layers lets you be specific in what you want to turn on and off in each view. Creating these layers early also means you don’t have to go back in the end and retroactively delete items or change their layer.

- Clean up the drawing: As you finish your drawing, make sure you delete any features that are unneeded or trash. Check your layers for leftover bits from changes you might have made earlier. Make sure there’s nothing forgotten at the extents of the drawing that’s no longer needed. Removal of clutter and less overlap of lines makes a drawing easy to read for anyone else.

- Google it: I’ve come to discover that whenever a person has a computer problem they tend to do the same thing--freak out for 15 minutes trying to fix it, sit there thinking their problem is somehow unique to them, and make some comment on being “cursed” using technology. I’d say unless your computer spontaneously combusts, then someone else has had the same problem before. Before you waste too much effort trying to fix your CAD problem, try a Google search. There are forums dedicated to people with almost any problem you can think of. This should be your first step when things go wrong and will save you on a lot of time.

What’s your favorite CAD tip? Please share your thoughts below.

Comments

Steve Smith says:

3/24/2023 06:30 AM

I love that you talked that saving all the projects ahead of time could help prevent losing your files and data. The other night, my best friend told me he and his business partner were hoping to find a CAD drafting service that could offer CNC servicing process for their steel business product. He asked if I had any thoughts on the best option to consider. I appreciate this helpful article.

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.