Robotic Cell Layout Considerations

Matt Kohler | 09 October 2015

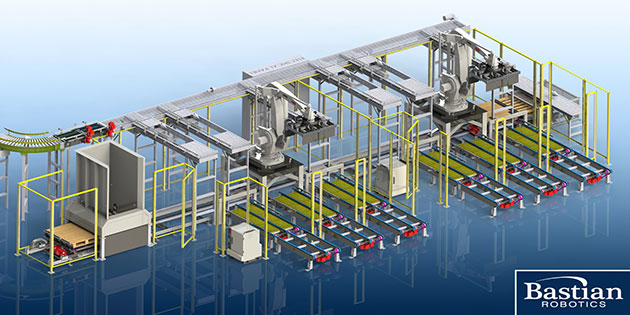

The layout of your robotic cell is crucial to its success. To ensure you have the most efficient layout for your facility, follow these five stages.

There are many avenues in which an end-user begins to contemplate integrating a robotic cell into his or her facility. It may be an organic conception from a project manager, something that was witnessed in another organization’s facility, a mandate from upper management, or one of many other unmentioned reasons. In its infant stages, a project will typically state the goals before any strategies are set in place to achieve these goals.

In a robotic application, many times these goals are safety, labor cost, throughput, or ergonomically-based. Once the system type is defined, technical requirements are stated, and the goals are established, one of the most crucial ingredients to a successful project is an efficient system layout.

In this article, I look to group the robotic cell layout development process into five separate chapters: Requirements, Concept, Constraints, Strategies, and Results.

The Requirements

The first step in laying out a fully functional system is for the Application Engineer to understand the space and product flow requirements. With facility real estate at a premium, it is of prime importance to minimize the system footprint while not constricting operator access, forklift travel, material transport, or egress routes. At this stage, facility personnel or project managers typically provide high-level criteria in which the Application Engineer must adhere to. These requirements typically take the form of the following:

- Product infeed locations

- Raw material delivery locations

- Forklift travel aisle ways

- Structural obstructions to avoid

- Desired cell access points

- Existing equipment tie-in points

- Energy drop locations (electrical, air)

- Clear height available below roof structure, fire protection, piping, mezzanines, etc.

Understanding all these requirements upfront will allow the Application Engineer to design an efficient and maintainable robotic cell that will meet the expectations of the customer. It is, many times, not until later in the layout development (the Concept Stage) when additional plant personnel (i.e. plant managers, maintenance, etc.) provide additional input on specific access and travel requirements within the plant floor.

The Concept

Application Engineers have many tools at their disposal to represent the conceptual layout of a proposed robotic system. Some of these tools include:

- 2-Dimensional CAD

- 3-Dimensional SolidWorks renderings

- 3-Dimensional simulations

Depending on the complexity of the system layout, each of these tools provides a different level of visualization in order to fully understand the operation and space requirements of a robotic cell. Initial conceptual designs typically begin with a simple 2-D layout. This allows for easy manipulation of equipment locations based on discussions with the customer.

Once a general acceptable layout has been agreed upon, 3-D representations can provide another level of evaluation to give the customer a better idea of how the system will fit into his or her facility. While these initial layout discussions may go smoothly, the inclusion of additional customer representatives to critique the layout can many times add new constraints that must be addressed prior to implementation.

The Constraints

Every customer representative included in the design review process has a unique perspective on the challenges of implementing a new robotic cell into their existing facility operation. Some of these different perspectives focus on material flow, some on preventative maintenance access points, some on aesthetics, and some just don’t want to see any changes made to the facility they have grown accustomed to working in. Each perspective poses additional challenges to the Application Engineer and customer representative charged with moving the project through the approval process towards implementation.

The key to a successful project, however, is not in avoiding these perspectives or excluding opposing viewpoints from adding input into the design. The key is quite the opposite: Involve as many representatives as possible early in the process to identify and address key constraints. It is much more difficult to manipulate a layout at the 11th hour than in the early conceptual stages. While every effort is made to foresee all potential issues in the infant stages of a project, inevitably challenges will arise in later stages that must be addressed. When these hurdles present themselves, there are preferred methods of tackling them without detouring the project development.

The Strategies

There are many strategies that can be used to manipulate a robotic cell layout to reduce footprint, re-route material flow, or provide enhanced accessibility for operators. Some commonly used tactics include:

- Minimizing wasted space in center of cell.

- Utilizing the “z” (vertical) direction as much as possible by elevating equipment, robots, or conveyor.

- Reducing conveyor widths to match product or pallet size as close as possible.

- Only providing the level of automation needed to accomplish the goals of the project.

- Robot control options which allow for safety fencing to be closer to robot reach points.

- Only provide the amount of product or load accumulation needed to accomplish the goals of the project.

- Use lift gates or embed components into the floor slab to allow additional accessibility.

The Results

From the infant stages of a design to a fully functioning robotic cell, the development of a project and its respective layout requires input and attention from several customer and supplier representatives. Information from project managers, maintenance personnel, operators, and management all contribute a piece of the puzzle that will lead to accomplishing the initial project goals. Everyone on both sides of the project must understand there will be differences in opinions, logistical and technical challenges, and 11th hour requests throughout the process. However, by keeping the lines of communication open and approaching the project in a routine step-by-step process, various strategies can be used to produce a solution that will be beneficial to everyone involved.

From the infant stages of a design to a fully functioning robotic cell, the development of a project and its respective layout requires input and attention from several customer and supplier representatives. Information from project managers, maintenance personnel, operators, and management all contribute a piece of the puzzle that will lead to accomplishing the initial project goals. Everyone on both sides of the project must understand there will be differences in opinions, logistical and technical challenges, and 11th hour requests throughout the process. However, by keeping the lines of communication open and approaching the project in a routine step-by-step process, various strategies can be used to produce a solution that will be beneficial to everyone involved.

Matt Kohler, Bastian Solutions Director of Applications has been with Bastian Solutions since 2005, after receiving his degree in mechanical engineering from the University of Missouri - Columbia. The applications team at Bastian Solutions prides themselves on thoroughly understanding their customer’s unique needs and then tailors a solution that gives those customers a competitive edge in their business.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.