3 Steps to a Great Turnkey Material Handling System

Jonathan Syrett | 20 August 2015

A turn-key material handling solution is the complete design, build, and installation of material handling equipment. This type of solution allows you to work with one company to ensure your project exceeds expectations from start to finish. Below I have outlined the different aspects of a turn-key system and what you can expect during each phase.

Step 1: Design

Each engineering project is conceived and executed holistically while focusing on our customer’s specific business and technical objectives. The design phase consists of formulating detailed functional specifications, consistently providing schedule/milestone status updates, and conducting comprehensive design reviews with the customer. The design process typically begins with a kickoff meeting where scope, layout, and specifications are discussed. Layouts are then subsequently generated, and individual pieces of equipment are designed. Those designs are then reviewed, and a final system design is produced.

Step 2: Build

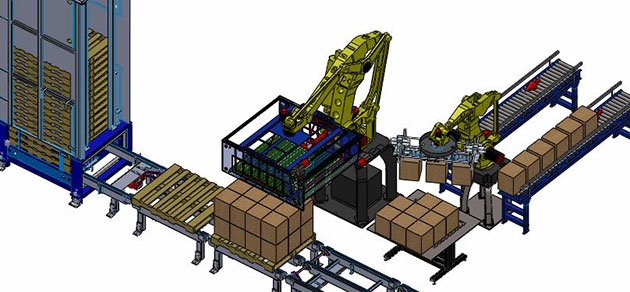

After the design phase, projects at our robotics manufacturing facility transition to the shop floor where ample space is dedicated to assembling the system. Fabrication of system components and the control panel are all completed in house, and then our experienced assembly crew utilizes top quality parts to provide a durable, long lasting system. Once fabrication and assembly is completed, our engineers test and refine the system before a final acceptance test. Acceptance testing is conducted in our manufacturing facility, allowing the customer to view the system prior to shipment.

Step 3: Installation and Support

In addition to designing and building the system, installation support, commissioning, startup and training are available to customers on a per day basis, and system support is available 24/7 through our customer service department. When executing a turn-key project, we also offers a dedicated project manager to facilitate communication with the customer throughout the lifecycle of the project, including installation.

Bastian Solutions has the ability to produce a turn-key package by utilizing its multiple business units from software to robotics and custom manufacturing/engineering. Whether you need custom automation equipment, a warehouse software package, robotics system or all of the above, our team can assist you in the design, build, and installation of the turnkey solution.

Our experience also spans multiple industries, so if you are looking for a turnkey material handling system, please contact us. Our engineers are happy to assist in your next project.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.