3 Industrial Lift Table Uses Safety Officers Would Hate

Chelsi | 25 September 2015

Industrial lift tables are useful tools for your plant or warehouse, so useful in fact, one might want to deploy them in other situations.

Discussing the benefits of an industrial lift table can be a no-brainer for professionals who use them regularly. From the ergonomic benefits to the efficiency in moving products of any size, lift tables provide a great advantage for the difficulties of product distribution. Correctly operating a lift table that is specific to your distribution center’s needs is critical for optimal performance and employee safety. While lift tables provide a great solution for many industrial situations, taking them out of their specified work zones and using them for purposes unrelated to their intended functions could prove to be disastrous. The following safety graphics will help explain the importance of operating industrial lift tables for their intended purposes only. These graphics are intended for laughs only and are not recommended for trying at home.

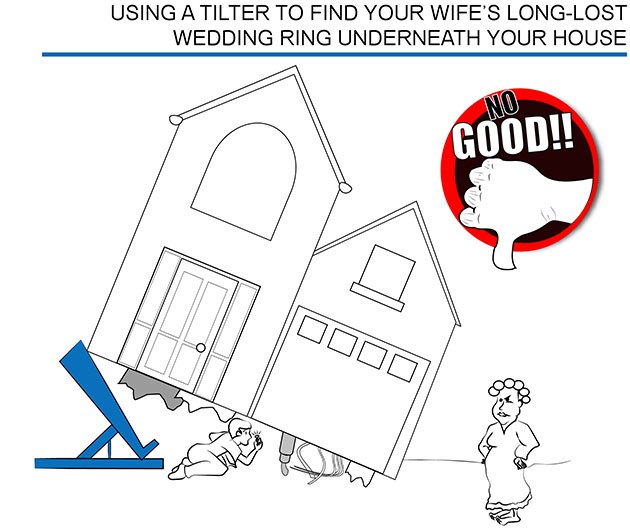

Industrial Tilt Tables

Closely related to lift tables, the tilt table is a great way to take care of common tasks related to positioning and re-orientating loads. Tilters can tilt products up to 120 degrees and can be customized to fit specific needs based on weight and size of specific product(s). While commonly used in warehouse and distribution settings for ergonomic product handling, the tilt table has not been proven effective at elevating houses from their foundations to recover lost goods such as wedding rings. Pursuing this idea will likely cause serious damage to your home and turn your family bitter toward you. Please use caution when operating this machinery and be sure to leave it in its intended location.

Scissor Lift Tables

Scissor lift tables are popular solutions that come in a wide variety of configurations for specific needs. These dependable lift tables are capable of moving loads of just about any size as long as they are properly engineered to do so. While some designs come in a portable option, it is not recommended to use these tables for purposes other than what they were designed for. For instance, using a portable scissor lift table to carry someone’s personal items up to the fourth floor of a dormitory won’t end happily because these lift tables only travel about 20 feet high. Either someone needs to move to the second floor of the building or you might consider hiring a moving company.

Scissor lift tables are popular solutions that come in a wide variety of configurations for specific needs. These dependable lift tables are capable of moving loads of just about any size as long as they are properly engineered to do so. While some designs come in a portable option, it is not recommended to use these tables for purposes other than what they were designed for. For instance, using a portable scissor lift table to carry someone’s personal items up to the fourth floor of a dormitory won’t end happily because these lift tables only travel about 20 feet high. Either someone needs to move to the second floor of the building or you might consider hiring a moving company.

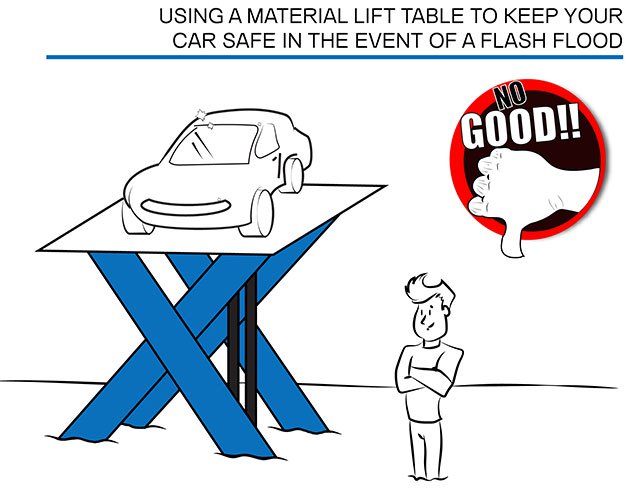

Heavy-Duty Lift Tables

Heavy-Duty lift tables are fully capable of lifting heavy equipment such as pallets or vehicles. They are also capable of operating in hostile environments such as freezers. As long as the tables are properly configured for their intended environment and use, there should be no issues. For instance, using a hydraulic lift table for food and beverage products will require a food-grade hydraulic fluid to operate. Nonetheless, using a lift table for vehicle safety during a flash flood is not an intended use for industrial lift tables. The flooding could prove hazardous to the operation of the lift table, causing a terrible fate for your set of wheels. It’s best to follow proper safety guidelines for flash flooding and, perhaps, build a house with a garage on a good hill.

Heavy-Duty lift tables are fully capable of lifting heavy equipment such as pallets or vehicles. They are also capable of operating in hostile environments such as freezers. As long as the tables are properly configured for their intended environment and use, there should be no issues. For instance, using a hydraulic lift table for food and beverage products will require a food-grade hydraulic fluid to operate. Nonetheless, using a lift table for vehicle safety during a flash flood is not an intended use for industrial lift tables. The flooding could prove hazardous to the operation of the lift table, causing a terrible fate for your set of wheels. It’s best to follow proper safety guidelines for flash flooding and, perhaps, build a house with a garage on a good hill.

Industrial Lift Table Safety

Operating a lift table within its intended purposes and environment can provide an invaluable solution for your industrial needs. While it might be tempting to use this tool for extra-curricular projects, make sure your lift table is properly configured for the task at hand before operating. To ensure safe use of these products, we recommend:

- Properly training all employees on lift table use and safety

- Inspecting the equipment annually

- Never exceeding the table’s maximum capacity

For any questions regarding the use of an industrial lift table, please contact us. One of our experienced engineers would be happy to take your call.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.