3 Factors for Proper Roll Handling

Bastian Solutions | 19 July 2018

The key to proper roll handling is collecting the right product data.

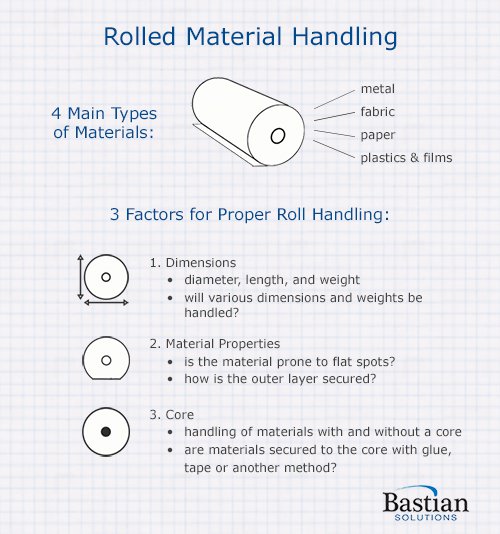

Roll products usually consist of four main materials that are used to make many finished products, including metals, plastics/film, paper and fabrics. When deciding which equipment is needed to handle roll products, there are key product elements that must be considered. Here are the most important factors for proper roll handling.

Product Dimensions

Understanding the dimensions of any product is crucial to determine proper handling, but with roll products there are a couple of things to consider. The dimension data required is outer diameter, width/length and maximum weight. The outside diameter is one of the most important measurements because of the relationship it holds with the maximum weight of the product. Depending on the density of the material and the general dimensions of the roll, the slightest increase in the outside diameter can result in a significant increase to the weight. It is important to know if different size diameter rolls will need to be handled to ensure the equipment can tolerate the variance in weights.

Material Properties

If a product must be placed on its side, it’s important to note if the material is susceptible to creating a “flat spot” due to its own weight and material properties. This will determine the size and angle of the vee in a pan or deck for containing the roll. If the product is to be rolled/dumped, understanding the flat spot will help determine how long of a runway will be needed or at what angle. In addition, common operations for plastics and fabrics require that the loose piece of material on the outside of the roll be cut out and sent to QC. Once this piece has been cut, it is important to know how the loose material will be secured to prevent the roll from unraveling.

Core

The next aspect to consider is whether the roll has a core. Most rolled products utilize cores, but some materials, such as metals, are exceptions. The core plays a very important role in the handling operation. Materials that can be damaged if handled around the circumference must be lifted or held by the core. To do this properly and safely, the dimensions of the core need to be known as well as the method of securing the product to the core. The two most common methods are tapes and glues. This information is more important if core prep is part of the handling process. However, if the product being handled does not have a core, this becomes more of an issue depending on the type of material. More ridged material such as metals are not as problematic as soft plastics and fabrics.

The key to any material handling operation is the collection of product data. For roll handling, the most crucial pieces of information to have are final product dimensions, material properties and information about the core. Understanding these key factors will determine the proper course of action needed for the desired handling operation.

Bastian Solutions, a Toyota Advanced Logistics company.

We are a trusted supply chain integration partner committed to providing our clients a competitive advantage by designing and delivering world-class distribution and production solutions.

Our people are the foundation of this commitment. Our collaborative culture promotes integrity, inclusion, and innovation providing opportunities to learn, grow, and make an impact. Since 1952, Bastian Solutions has grown from a small Midwest company into a global corporation with over 20 U.S. offices as well as international offices in Brazil, Canada, India, and Mexico.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.